Long before specialty amines filled pharmaceutical pipelines or colorants for our synthetic textiles, people looked to simple organic compounds for new directions in industry. T-Butylamine came to the scene during the feverish chemistry boom of the early-to-mid twentieth century. Many early chemists saw it as just another nitrogen-containing building block—handy, reactive, with an odd nutty smell. Back then, amine chemistry was rough-and-tumble, often relying on basic distillation and ancient glassware to isolate new compounds. Through the decades, researchers improved synthesis techniques. The arrival of cleaner alkylation routes and a deeper understanding of amine behavior allowed bulk production of T-Butylamine, giving it a steady role in research labs and on the manufacturing floor. I remember flipping through old chemistry journals in college—patents from the 1950s and 60s prioritized amines as chemical keys to everything from rubber accelerators to new pesticides. T-Butylamine played quiet but crucial parts in those experiments, slowly earning its stripes alongside compounds like ethylamine and diethylamine.

T-Butylamine usually comes as a clear, colorless liquid. It’s got a sharp, fishy odor that tends to stick around even after a good wash-up. Weight for weight, it packs a surprising punch—volatile, lighter than water, and quick to evaporate. Beyond its laboratory reputation, this stuff slips into various industrial roles. It can stand as an intermediate for insecticides, pharmaceuticals, even some rubber-sized molecules. I saw several production lines depend on it in my chemical plant days, with operators measuring it out for a batch and carefully venting fume hoods to handle its smell.

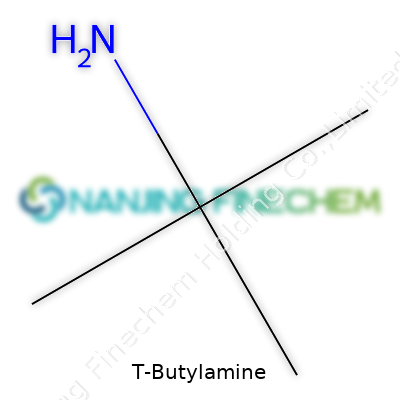

T-Butylamine holds the formula (CH3)3CNH2. It boils around 44°C—just above room temperature on a summer day—and has a melting point well below freezing at -51°C. Its density comes in at about 0.74 g/cm3, so it floats over water. The amine group (-NH2) makes this compound notably basic—the lone pair of electrons on nitrogen likes to grab onto protons, or form bonds with acids. Its vapor tends to catch fire, so storage and shipping require tight seals and moderate temperatures. Some chemists look at its structure and immediately recognize the classic “tert-butyl” effect: bulky branches, low reactivity at the carbon, but the nitrogen atom stays available for many reactions.

Standard specifications matter for T-Butylamine buyers and sellers. Most chemical suppliers sell it at purities above 99%. Labels list batch numbers, impurity levels, and expiration dates. I have seen shipping drums backed up by lots of paperwork—hazard class, UN number (for T-Butylamine, it’s 2733), and a clear skull-and-crossbones for its flammable and toxic nature. European regulations use GHS pictograms and specify everything from maximum water content to allowable traces of byproducts. Lab operators often wear full-face respirators, heavy gloves, and sometimes even refrigerated suits—not just for show, but because a single spill can clear a room in minutes.

The classic approach to T-Butylamine involves reacting ammonia with isobutylene or tert-butyl alcohol under acid catalysis. Sometimes, chemists explore reductive amination, using formaldehyde and ammonia with a reducing agent. In one plant I visited, they favored continuous flow reactors, slowly dripping ammonia into a preheated coil lined with isobutylene. After quenching, the vapors passed through condensation columns, and the resulting liquid settled into drums for distillation. This synthesis avoids complicated steps, but the exothermic reaction and potential for byproduct formation mean calibrated controls are vital. Every batch needs purity checks, because unreacted feedstock and minor amines build up fast without attention.

T-Butylamine stands out for its reactive nitrogen. It forms amides with acid chlorides, tucks into alkylation reactions, and seamlessly creates Schiff bases with aldehydes or ketones. In organic labs, chemists like using it for introducing the tert-butyl group—a massive substituent that gives molecules steric bulk, changing how enzymes or catalysts grip them. I recall experiments using T-Butylamine to block one side of a reaction, making selectivity easier to achieve. Its reactivity tailors it for drug discovery, dye manufacture, and even polymer stabilization chemistry. The molecule’s size means it fights for space—handy if you want to stop unwanted side reactions.

Flip through a few safety sheets, and T-Butylamine comes with a host of aliases: tert-Butylamine, 2-Methyl-2-propanamine, TBA, t-Butylamine, and even the tongue-twister 1,1-dimethylethanamine. Catalogs from leading chemical suppliers include all these options. I’ve met old-timers who call it “TBA” on the shop floor, while labs print full IUPAC names for regulatory reasons. International clients may ask for it as TBA, so solid product tracking and understanding synonym lists keeps orders clear.

Safety standards around T-Butylamine draw from harsh lessons. Not long ago, chemical plants treated ventilation as a luxury, not a necessity—workers would handle drums without adequate face protection, risking toxic exposure. Today, facility managers invest in fireproof cabinets, robust LEV (local exhaust ventilation), and consistent gas detection systems. The compound’s flash point sits only a few degrees above room temperature, so any process leak can ignite. Spill kits stand ready with neutralizers for amines and plenty of absorbent pads. Training runs deep—anyone tasked with handling T-Butylamine practices emergency procedures more than the basics. Even the paperwork, from Material Safety Data Sheets to disposal logs, stays close at hand—regulatory audits expect nothing less.

People find uses for T-Butylamine anywhere tough synthetic chemistry calls for robust building blocks. It works as a raw material for pesticides—herbicides that use amines to dock with plant biochemical pathways, disrupting specific enzymes. It supports rubber and polymer production, especially in vulcanization accelerators. Pharmaceutical labs value it for its ability to build up larger, more complex drugs, offering tert-butyl groups as protective agents or structural modifiers. Certain dyes and pigments need the stability T-Butylamine provides; these formulations rely on its reactivity to build long, stubbornly non-fading colorants. I’ve worked with analysts who test water for pesticide runoff—T-Butylamine residues tell a story of which chemicals reach the fields and how long they stick around.

R&D teams keep pushing the boundaries for T-Butylamine, exploring new synthetic methods and safer ways to handle or modify the molecule. Green chemistry approaches—like using water as a reaction solvent or deploying biocatalysts instead of harsh persulfates—aim to minimize waste and emissions in production. Some pharmaceutical researchers eye T-Butylamine for its role in new active pharmaceutical ingredients (APIs), seeking custom functionalizations or alternative protective groups. Consortia in Europe and East Asia have tried to develop continuous processes, with in-line sensors reporting purity in real time. Modern workbench chemists routinely optimize conditions for T-Butylamine alkylation, mapping side reactions and trying novel catalysts that speed up desired product formation with less energy use.

Toxicologists keep a close eye on T-Butylamine because amines in general often irritate skin, mucous membranes, and airways. Animal studies show acute toxicity at high doses—rabbits, for example, developed breathing issues after inhaling concentrated vapors. Longer-term exposure in rodent studies pointed toward liver and kidney stress. Some epidemiological studies suggest industrial workers exposed to volatilized T-Butylamine, especially before modern safety controls, experienced more headaches and respiratory symptoms than the general population. Regulations ask for strict occupational exposure limits, and waste management teams use activated carbon filters and deep scrubbers to keep air concentrations below dangerous thresholds. Disposal protocols focus on incineration or careful neutralization since direct release would spark both safety and environmental alarms.

Looking to the future, T-Butylamine could see its role expand or shift as industries grow and reshape. If synthetic biology steps deeper into amine chemistry, enzymes might replace traditional copper or palladium catalysts, providing cleaner and faster routes to T-Butylamine derivatives. Water treatment facilities increasingly monitor small molecule contaminants—expect regulatory updates that ask for tighter control on discharge and air emissions. In energy storage, specialty amines crop up as potential components for new batteries or electrolytes; T-Butylamine may find niches in these areas, since its volatility and structure offer unique advantages. Advances in pharmaceutical design and agricultural technology also promise more demand, provided synthesis remains safe and scalable. I have noticed a steady stream of academic interest—new papers tackle everything from more sustainable preparation to high-value derivatives used in precision crop treatment. The future for T-Butylamine isn’t just about producing more, but finding smarter, safer, and greener ways to leverage this old but reliable chemical tool.

T-Butylamine likely doesn’t roll off the tongue in daily conversations, but it’s surprisingly present in corners of industry that reach most households. Picture this: painkillers you take for a headache, agricultural products sprayed to keep food growing, and even the ink in your favorite pen — connections trail back to this small, colorless, flammable liquid.

Medicine cabinets show evidence of t-butylamine without any labels mentioning it. Drug development, especially in creating active pharmaceutical ingredients, often requires reliable, quick-building blocks. T-Butylamine steps in here. It speeds up reactions during synthesis and helps build compounds that make some pain medicines work better. According to chemical industry reports, it enjoys heavy demand because it delivers results efficiently, helping chemists produce drugs in higher purity and yield with fewer headaches over byproduct cleanup.

Farmers don’t usually call up chemical suppliers asking about amines, but their crops regularly benefit from them. T-Butylamine contributes to making certain pesticides and fungicides. The goal always remains the same: healthy plants and strong yields. People forget just how many layers go into keeping those shelves fully stocked — a strong chain that includes reliable chemicals like this one. Without these agents keeping pests in check, harvests suffer, prices go up, and food supplies become less predictable.

Beyond medicine and food, t-butylamine turns up in glue, rubber, dyes, and lubricants. It helps make things that last longer, work better, or just hold together. From the handlebars on your bike to the books on your shelf, parts of modern life owe something to a lab process where this compound helped finish the job faster or with more stability.

Stories around chemicals like t-butylamine aren’t always sweet or simple. Its flammable nature and potential to cause irritation mean proper handling matters. I’ve seen workers handle similar amines with gloves, masks, and good ventilation — no shortcuts. Safety Data Sheets spell out the hazards, but real vigilance comes from remembering accidents won’t just hurt an operator; they can affect an entire community. Spills, leaks, even improper disposal, put water and soil at risk. Accidents in the past have led to regulations tightening for everyone’s good.

Spending years around labs taught me that every helpful compound eventually faces pointed questions. Could we find something less toxic, less volatile, less hazardous? Chemists explore greener alternatives — some plant-based, some relying on new synthetics — to keep industry humming without risking health or the environment. Efforts like these aren’t overnight fixes and require investment in research and willingness to test new paths, but people pay attention now in a way that felt rare a few decades ago.

T-Butylamine won’t become a household name, and that might be just fine. But whoever cares about safe food, effective medicine, reliable products, or clean water has a stake in how industry chemicals are handled. Each process, each product, tells a bit of a story, and t-butylamine’s chapter still unfolds quietly in the background of modern life.

Working with chemicals on any scale isn’t just about moving liquids from one drum to another. T-Butylamine, a clear liquid with a strong odor, comes with its fair share of headaches if care slips, especially in the storage department. Some folks might think it’s just a matter of finding a spare corner, but that approach can backfire. Exposure to air and moisture or storing near heat sources can spell disaster. I’ve seen stories of leaky drums and ruined stock because a team overlooked how this material behaves.

T-Butylamine lights off easily. Its flash point sits dangerously low—below room temperature. The fumes can catch fire from a tiny spark. For anyone with a background in chemical storage, these numbers aren’t just technicalities—they’re red flags. I remember a time at a small manufacturing plant where a forklift driver got careless, turning a routine delivery into a near-miss. The storage area was stuffy, with no real ventilation. Smell alone made me uneasy, but the risk went deeper than that. T-Butylamine evaporates fast, turning even a small spill into a fire hazard.

Chemical storage doesn’t always leave room for shortcuts. T-Butylamine tanks belong in a cool, dry spot, away from the hustle and bustle. Direct sunlight heats up containers, pumping up vapor pressure and making leaks more likely. I once caught a warehouse crew about to leave a drum next to a space heater to “keep it from getting too cold”—not realizing they were turning it into a bomb.

Containers should stay tightly closed. Metal drums work, but the inner linings matter. Corrosion sneaks up over time, especially if water gets in, so checking seals and lids pays off. Don’t stack containers near acids, oxidizers, or even food storage areas. T-Butylamine reacts with many chemicals, and a mix-up can lead to dangerous byproducts. Spacing matters, and it’s worth labeling an area to avoid confusion.

If you’ve ever opened a drum of T-Butylamine, you know the odor sticks with you for hours. Good ventilation isn’t just for comfort—it’s about keeping fumes from hitting dangerous levels. Even if the law doesn’t spell out minimum air changes, anyone who’s spent time in a poorly ventilated space knows why it matters. A simple exhaust fan can make the difference.

Leaks start small and often don’t look like disasters at first glance. Drums should be checked regularly—look for swelling, corrosion, or wet spots. Chemical-absorbent pads and spill kits need to stay nearby, not locked away across the building. From my experience, dealing with a minor leak quickly is easier (and cheaper) than trying to handle a full-blown cleanup.

Rules and checklists don’t do much unless everyone buys in. Sometimes, old-timers trust their nose over a warning label, but that’s a fast lane to trouble here. Training pays off—walking crews through what to look out for, showing what happens if a drum fails, and practicing spill response.

T-Butylamine demands respect. Paying closer attention to storage isn’t about paperwork or being a stickler for rules. It’s about keeping people safe, protecting investments, and avoiding nasty surprises. In my experience, a few extra steps in storage cut risks more than any fancy equipment after an accident. Simple habits, kept every day, keep situations under control.

T-butylamine sounds like one of those chemicals most people never consider. If you’ve worked in a lab, though, you know these sorts of chemicals show up often. T-butylamine helps with synthesis in pharmaceuticals and even ends up in agricultural chemicals like pesticides. Easy to grab from chemical suppliers, it doesn’t scream danger at first glance. But get it on your skin or breathe too much of the vapor, and you’ll remember why decent safety habits make a difference.

This chemical falls into a category called "amines," which often carry pretty sharp odors. If you’ve ever taken a whiff of ammonia or certain cleaning agents, you get the drift. T-butylamine packs a serious punch for your nose—just a small spill makes a room unlivable in minutes. Its vapors irritate eyes, nose, and throat faster than you’d expect. Prolonged exposure causes headaches, dizziness, or even damage to the lungs. On your skin, pulling off gloves and realizing that tingling isn’t normal can be a rude wakeup call—contact leads to redness and, in some cases, full-blown burns.

My first encounter with t-butylamine came in a grad school lab project. I mixed it for a reaction and learned quickly that even a tiny drop on the bench can turn the whole room sour. Colleagues who got careless paid for it with watery eyes and coughing fits. Someone forgot safety glasses, and his eyes hurt for days. This chemical isn’t forgiving.

Volatile chemicals create real fire risks, and t-butylamine fits this profile all too well. Spills don't just pose inhalation hazards—they leave flammable vapors behind. This stuff has a low flash point, which means a spark from static electricity or a nearby hot plate gets dangerous in a hurry. Warehouses have lost inventory to explosions when workers didn’t follow strict grounding or ventilation rules. It’s not just about following paperwork rules; it’s about avoiding a call to the fire department.

You don’t need fancy systems to keep safe. Start with core habits: always keep t-butylamine containers closed unless you’re pouring. Store them away from heat, open flames, and oxidizers—don’t treat the chemical shelf like a pantry. Use chemical-resistant gloves and splash-proof goggles. An apron isn’t overkill, either, especially during transfer or cleaning.

In smaller spaces, always run a fan or open a window. Fume hoods take away much of the risk if you have access to one. Most injuries happen when people trust too much in their lab’s air exchange system or take off safety gear for "just a minute." I’ve seen folks shortcut the rules and regret it. Rubbery gloves and careful handling matter lots more than folks expect.

Have clean water ready for splashes, and know where the eyewash station is. In a small startup lab I worked in, labeling made the difference—unmarked bottles led to a mix-up that nearly resulted in a nasty burn. Double-checking before pouring beats an emergency room visit. Clean up spills promptly using proper absorbent, and bag any waste as hazardous. Caution beats cleanup every time, but an emergency plan helps mop up the mistakes.

A chemical like t-butylamine brings value to industries and science, but it doesn’t offer second chances for sloppy habits. Treating it with respect isn’t about fear—it’s about not learning safety the hard way. Rely on gloves, goggles, good sense, and label everything twice. That’s where safety comes from, not big words in a binder.

T-Butylamine, often spotted in laboratories and chemical plants, packs a punch well beyond its compact molecular shape. This simple-looking compound, with the chemical formula C4H11N, sits at a fascinating crossroads where organic chemistry meets industrial demand. The structure tells its own story: you get a nitrogen atom (that’s the “amine” part) stuck onto a branched carbon backbone known as tert-butyl. Picture three methyl groups (CH3) fanning out from a single carbon, with the amine (NH2) group hanging off the central hub. If you’ve ever handled this clear liquid, you won’t soon forget the strong, ammonia-like whiff it gives off.

T-Butylamine doesn’t just pop up by chance; its layout actually decides how people put it to work. That bulky, branching tert-butyl shape (sometimes written as (CH3)3C-NH2) creates unusual stability and reactivity. From my own days pouring over synthesis routes, the sterics — meaning the crowded, chunky nature of this molecule — either help or hinder, depending on the goal. Chemists gravitate toward it for jobs where other amines might react too quickly or uncontrollably. For example, it slides into the synthesis of pesticides, drugs, and fuel additives. That’s direct impact; a little bottle on a bench turns into cancer-fighting drugs or solutions that keep engines clean.

Of course, nothing in chemistry comes risk-free. T-Butylamine’s sharp smell hints at its hazard. It burns skin, irritates lungs, and in larger doses, can deliver a nasty jolt to anyone working without proper protection. This is not guesswork. Industry data pinpoints it as flammable and harmful if inhaled. Honestly, the first time handling it, I learned the hard way that even sturdy gloves only last so long. Accidents drive change, though. Refineries and pharmaceutical labs now shore up protocols — closed storage, well-ventilated hoods, emergency showers. Education about dangers doesn’t slow anyone down; it sharpens focus, encouraging better respect for potent molecules.

Sometimes, T-Butylamine gets overlooked in favor of splashier chemicals. But this little amine holds plenty of value across a range of fields. It acts as a building block for anti-diabetic medications, corrosion inhibitors for ferocious industrial conditions, and accelerators for rubber processing. Even the food industry takes an interest, employing it in specialty flavor compounds after careful purification. Most folks outside the lab never realize how many products develop thanks to behind-the-scenes molecules like this one.

No chemical runs wild without oversight anymore. Regulators, industry leaders, and educational programs all take aim at safer handling. Upgrading equipment minimizes leaks, and ongoing training beats complacency. I’ve seen old practices replaced by smarter, tech-driven solutions — real-time sensors that sniff out escapes, online courses that turn dry manuals into memorable safety lessons. The industry, in focusing on responsibility, has dramatically reduced injuries and environmental spills tied to volatile amines like T-Butylamine.

People who work with T-Butylamine know its quirks and uses. The chemical formula C4H11N captures more than just numbers; it points toward a web of innovation, risk, and progress. The structure underlies real chemistry that shapes industries and everyday life. Smart management and continual learning keep dangerous mishaps at bay, ensuring T-Butylamine remains more asset than threat in the toolkit.

T-Butylamine gets a lot of use in labs and factories every day. This stuff isn’t mysterious or hard to figure out. What hits first for anyone working with it is its strong smell. No mistaking it on a plant floor or in a warehouse.

My own days around chemical storerooms started with a checklist: containers, labeling, spill kit, ventilation. Most suppliers stick with metal cans or steel drums when dealing with T-butylamine on a larger scale. For research settings or smaller jobs, high-density polyethylene bottles (HDPE) hold the liquid just fine. No fancy glass packaging here—the material eats through a lot, but HDPE keeps it in line, especially if you store it right.

Anyone handling this amine knows that leaks go sour fast—both for worker health and equipment. You keep this liquid away from flames, sparks, or simply the wrong kind of cap. For that reason, metal pails with extra sealing rings are a favorite for those moving gallons, while glass is out of the question. A poorly tightened lid or a cheap plastic drum, and suddenly everyone knows you have a problem before you do.

Big shipments from chemical suppliers arrive sealed up tight. They carry a DOT flammable sticker, usually in 200-liter drums for industry or 20-liter cans for smaller outfits. No one wants evaporation losses, so everything stays locked down with vapor-tight liners. If anything leaks, the smell tells you to clear out fast.

From a safety point of view, the package means more than just a container. Every time a drum rolls in, I check for corrosion and the integrity of tamper-evident seals. Even short delays in loading docks can cause weight loss through the seal. For smaller quantities, UN-rated containers go the extra mile. Insurance, compliance, and local fire codes—all push handlers toward keeping everything labeled flammable and toxic, double-checked by safety officers and the people on the ground.

Anyone who’s been through a spill drill or a real incident knows the drill: Safety goggles, gloves, plenty of ventilation, and never cut costs on secondary containment. Fact—just one quart of T-butylamine in the wrong spot turns routine work into a scramble. Federal regs (like those from OSHA and the EPA) push everyone to track each bottle right from storage to disposal.

Problems pop up most often during transfers. Pouring from big drums means working with dispensing pumps that can handle pressurized vapors without risking static sparks. I’ve seen too many people ignore grounding wires and get lucky—a spark could set things off. Once, someone caught a container without a ground strap and learned the hard way. Best practice is using bonded and grounded systems, limiting open-air transfer, and treating even the last drop with respect.

There’s a push today to improve container return programs and recyclability for these materials. It’s slow-going, since chemical residues and flare risks never really disappear, but it’s something. Bulk users push for better-designed returnable drums, along with real investment in tracking systems. This keeps genuine safety in the loop.

So, what matters most? Real-world caution, constant inspection, and a willingness to speak up if a drum looks sketchy. Taking shortcuts with T-butylamine supply and packaging just isn’t worth the risk for anyone. It comes down to experience, not just regulations—no one forgets their first incident, but the smart ones prepare so it never happens again.

| Names | |

| Preferred IUPAC name | 2-Methylpropan-2-amine |

| Other names |

2-Methyl-2-propanamine tert-Butanamine t-Butanamine Tertbutylamine TBA |

| Pronunciation | /tiːˈbɜːrtəl.əˌmiːn/ |

| Identifiers | |

| CAS Number | 75-64-9 |

| 3D model (JSmol) | `3D model (JSmol) of T-Butylamine: CN(C)(C)C` |

| Beilstein Reference | 1718733 |

| ChEBI | CHEBI:63919 |

| ChEMBL | CHEMBL511 |

| ChemSpider | 6923 |

| DrugBank | DB01955 |

| ECHA InfoCard | 100.007.945 |

| EC Number | 200-889-2 |

| Gmelin Reference | 8233 |

| KEGG | C01627 |

| MeSH | D013663 |

| PubChem CID | 6379 |

| RTECS number | YN0175000 |

| UNII | K9BN01MN0N |

| UN number | UN1125 |

| Properties | |

| Chemical formula | C4H11N |

| Molar mass | 73.14 g/mol |

| Appearance | Colorless liquid |

| Odor | Ammonia-like |

| Density | 0.740 g/mL at 25 °C |

| Solubility in water | Miscible |

| log P | 0.7 |

| Vapor pressure | 10 mmHg (20°C) |

| Acidity (pKa) | 10.7 |

| Basicity (pKb) | 3.38 |

| Magnetic susceptibility (χ) | -44.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.374 |

| Viscosity | 0.392 mPa·s (at 20 °C) |

| Dipole moment | 2.29 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 255.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -69.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3898 kJ/mol |

| Pharmacology | |

| ATC code | C02CC06 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Danger |

| Hazard statements | H225, H302, H314, H332 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P302+P352, P304+P340, P305+P351+P338, P311, P312, P321, P337+P313, P370+P378, P403+P235, P405, P501 |

| NFPA 704 (fire diamond) | 3-3-0 |

| Flash point | -18 °C |

| Autoignition temperature | 285°C |

| Explosive limits | 1.7-9.8% (in air) |

| Lethal dose or concentration | LD50 oral rat 288 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 4,000 mg/kg |

| NIOSH | KN4550000 |

| PEL (Permissible) | 5 ppm |

| REL (Recommended) | 35 mg/m³ |

| IDLH (Immediate danger) | 100 ppm |

| Related compounds | |

| Related compounds |

tert-Amylamine tert-Butyl alcohol Butylamine sec-Butylamine Isobutylamine |