The story of malononitrile goes back to the late 19th century, with early references cropping up in studies of organic chemistry that shaped the modern field. Early chemists recognized the active methylene group in malononitrile, showing it behaves in a way that grabs attention from anyone interested in carbon atoms and reactivity. Back in the days of glassware and smoky labs, researchers pursued the synthesis of new dyes and complex intermediates, often landing on malononitrile as a reliable building block. Its introduction allowed generations of chemists to expand the toolkit for constructing everything from agricultural chemicals to pharmaceuticals. Today, this molecule continues to anchor bench work in both academic and industrial labs, signaling a deep legacy.

Malononitrile doesn’t look like much at first glance—a small, colorless solid with a mild, bitter odor. Chemists see it as more than that. This compound serves as a starter for multi-step syntheses, acting as a key piece in forming carbon–carbon bonds. In practice, malononitrile turns common laboratory dreams into reality by linking simple starting materials into complex frameworks. Packing two nitrile groups around a central carbon gets you both versatility and a bit of punch, since these groups pull electrons and make that central carbon eager to react.

Malononitrile’s physical properties tell you a lot about its personality. It melts around 32°C, making it easy to handle under standard conditions, and boils near 222°C. The solid dissolves nicely in water, ethanol, and a range of organic solvents. Its chemical reactivity stands out—those nitrile ends are electron-hungry, and this pushes the single methylene group into becoming a hot spot for chemical reactions. Acidic in nature, malononitrile’s central hydrogen atoms come off easily, opening up many routes for transformation. The strong electron-withdrawing effects carve out its place in organic synthesis and keep it as a favorite in the chemist’s drawer.

You spot malononitrile bottles sporting labels like “purity >99%” and “water content <0.5%,” and these aren’t just numbers for show. Reactions in pharmaceuticals and materials science call for meticulous control, since trace impurities might throw a synthesis off course. Handling instructions come printed alongside hazard symbols—reference numbers CAS 109-77-3 and UN 2811 signal the need for care in storage and use. Material safety data sheets go deep, stressing the need to avoid inhalation, wear gloves, and store away from open flames. You notice labs enforcing batch tracking and rigorous logs to keep mistakes and contamination out.

Synthesizing malononitrile isn’t rocket science for an organic lab—condense chloroacetic acid with sodium cyanide in water, drive the reaction under slightly alkaline conditions, and malononitrile eventually settles out. For production on a large scale, equipment scales up, but the chemistry sticks with the basics. You want high yields, so process optimization gets attention: controlling temperatures, minimizing side reactions, purging impurities, and using straightforward filtration or distillation. In industrial plants, engineers keep a close eye on equipment integrity and waste management, since using cyanide means you trade convenience for the need to contain toxicity.

Malononitrile jumps into action in all sorts of reactions, thanks to its active methylene group. Knoevenagel condensations, Michael additions, and cyclizations come straight to mind. I’ve seen lab mates use malononitrile to build barbiturates, pyridines, and heterocyclic compounds that would stump you if you tried a more direct route. Chemists appreciate the flexibility: alkylate the methylene carbon, hydrolyze to get interesting acids, or use its electron-poor center to control the reactivity in tough reactions. Some even graft other functional groups onto it, expanding its role as a synthesis workhorse or chameleon in organic chemistry.

A bottle of malononitrile can wear many names: Propanedinitrile, dicyanomethane, or even “malonic dinitrile.” Catalogs list it alongside synonyms like cyanoacetonitrile, but the IUPAC name—propanedinitrile—makes it easy to cross-check suppliers. Whether sourcing for research or manufacturing, people track the same core chemical through different labels, but the fingerprints stay the same.

Labs don’t take chances with malononitrile—strict safety rules show respect for both chemical and human risks. The MSDS warns about skin absorption, eye contact, and inhalation. Small molecule, big hazard: malononitrile releases toxic fumes on heating and can form hydrogen cyanide if treated carelessly with acid. Labs call for gloves, fume hoods, and proper waste disposal, since exposure means trouble for lungs and nervous system. Transport regulations—outlined under UN codes—limit shipment and enforce containment. Over the years, stricter occupational limits have kicked in, driving better ventilation and training.

Malononitrile’s influence spreads far from the bench. It sits inside herbicides, lights up as a precursor in dye manufacture, and pokes its head into pharmaceutical syntheses. Agrochemical industries often reach for it to build nitrile-containing molecules that push back weeds. Chemical researchers use it to introduce new drugs, study enzyme mechanisms, or create sensor materials. Its role boosts the output from both small startups and huge corporations trying to put new chemistry on the market. For a molecule with two simple nitrile groups, malononitrile shapes up as a star in making functionalized compounds, specialty plastics, and electronic intermediates.

Development doesn’t slow down—companies and research groups test new reactions aiming for green chemistry wins, less-waste routes, and bigger selectivity. Enzyme-catalyzed syntheses, photochemistry, and flow chemistry approaches pop up to squeeze out more value per gram of malononitrile. Current R&D tackles better purification, methods for reusing spent reagents, and the search for catalysts that operate at room temperature. Instrument vendors compete to offer new analytics for monitoring trace impurities. Scientists map out new heterocycles, bioactive molecules, and diagnostic agents, leaning on malononitrile as the go-to pivot point in their plans.

Years of animal studies and case reports tell a consistent story—malononitrile isn’t something to get careless with. Its ability to release cyanide under some metabolic or environmental conditions adds extra risk. Exposure may cause headaches, dizziness, or worse, and long-term risks have not been fully ruled out. Fact sheets nudge users to avoid environmental release and record spills. Occupational health researchers push for continuous monitoring, keeping worker health at the front of policy discussions. In the community, toxicology panels look for safer analogs or practical alternatives, though malononitrile’s synthetic advantages still hold sway in most applications.

The outlook for malononitrile holds both excitement and challenge. As industries shift to cleaner and more sustainable methods, companies explore bio-based or less hazardous pathways, but malononitrile’s functionality keeps it in demand for now. Researchers continue to refine its chemistry, feeding the hunger for new molecules in medicine and materials science. Handling protocols grow stricter, especially as global regulation tightens. Whether industry pivots to greener processes or shifts production to keep up with environmental rules, malononitrile’s mix of tradition and innovation shapes its evolving role across science. Its history of utility makes it hard to replace, though every new project pushes for a safer, smarter approach.

Malononitrile shows up in places many of us might not expect, considering so few people have heard its name. My first encounter came during a college lab session, where safety glasses and steady hands set the stage for a lesson in organic chemistry. The smell stuck with me, sharp and unforgettable. What I later found out is that malononitrile’s usefulness goes far beyond that stuffy classroom—and, like a lot of chemicals, you’ll find it in the background of things we encounter every day.

Think about the backbone for dyes that color household items or textiles—the building process often starts with simple molecules, and malononitrile steps up early. Small but reactive, this compound makes it possible to stitch together more complex chemicals. Chemists lean on its two nitrile groups to set off several kinds of reactions. It’s these nitrile groups that help build pharmaceutical compounds, too. For big pharma, that matters: pain relievers, cardiovascular drugs, maybe even some cancer treatments owe parts of their origins to steps involving malononitrile.

Other users look a little different. The agrochemical world finds malononitrile handy when crafting ingredients for pesticides and herbicides. Unlike what you might expect, modern agriculture depends on robust chemistry for strong yields, and stuff like malononitrile oils the gears. You’ll also spot its fingerprints on photographic chemicals and certain resins.

Work on solar panels, sensors, and LEDs sometimes leans on compounds that trace back to malononitrile. In a research lab I visited, technicians used dyed solutions—some brewed from malononitrile-based reactions—to test how well solar cells soak up sunlight. The push for new, cheaper energy sources often starts in low-key labs with basic chemicals like this one.

Safety matters with malononitrile. Exposure to its vapors or any careless spill puts people at risk for irritation or something worse. It’s not the kind of thing that should linger on anyone’s hands. The right gloves, proper ventilation, and solid protocols count for everything. My time in industrial settings taught me this lesson: shortcuts only work until they don’t, and with something this reactive, that edge matters. Regulatory bodies hold industrial players to clear standards, but enforcement and education need steady reinforcement.

Accidents can push chemicals like malononitrile into the environment where they don’t belong—streams, soil, air near the facility. Small leaks, if ignored, slowly add up. I’ve watched teams scramble to address a spill, stooped over storm drains with absorbent material, all because someone wanted to skip a step. Manufacturers really have to treat waste and emissions as a top concern. Installing better monitoring systems, keeping records honest, and investing in cleaner synthetic methods go a long way.

Meanwhile, researchers want alternatives. Sometimes that means tweaking reactions to use less hazardous ingredients, or finding recycling routes for what would normally become waste. It’s hard work, but each step shrinks risk and waste, making life safer for workers and nearby communities.

Though malononitrile rarely grabs headlines, its presence touches medicine, farming, tech, and color. Each bottle, each shipment, each reaction should get the care it deserves—from lab bench to factory floor. The chemical’s story isn’t just about efficiency; it’s also about keeping innovation and safety in the same circle.

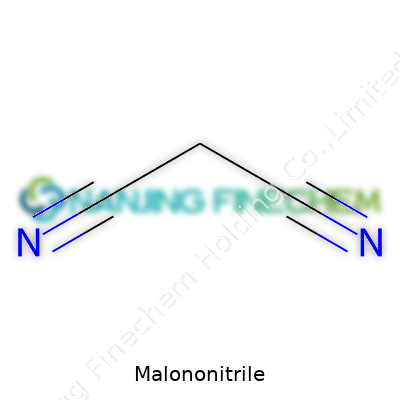

Think about a molecule that could fit in the palm of your hand if you could seemicroscopically small. That’s malononitrile, made up of three carbon atoms, two nitrogen atoms, and two hydrogen atoms. Its formula, C3H2N2, is simple, yet this compound tells a bigger story in chemistry.

Take its structure: at the center sits a CH2 group, with a pair of cyanide groups (–C≡N) clinging to each side. This configuration packs some remarkable reactivity into a tight, practical design. Two triple bonds between carbon and nitrogen stretch out from the carbon backbone. If you’d draw it out, each cyanide group extends from the central carbon, flanking it like arms outstretched. The molecule appears as NC–CH2–CN.

Malononitrile owes its punch to those cyanide groups. The electronegative nitrogens yank on shared electrons, making the central carbon more acidic than usual. That extra acidity means chemists can whip off one of its hydrogens much more easily than with other hydrocarbons. I remember seeing it in a college organic lab—drop a base in, and malononitrile leaps at the chance to give up a proton. This quality lines it up as a handy building block in synthetic chemistry.

It’s not just theory. In the world of medicine, those same features pop up in real-world applications. Pharmaceutical companies have learned to use malononitrile’s structure to build drugs, hunt for new materials, or test biochemical pathways. Its small but spicy structure slips into all sorts of chemical reactions, sewing together new carbon bonds like a seamstress joining fabrics. Without it, some medicine cabinets would look pretty empty.

There’s always a catch. Those cyanide arms, sharp and reactive, can also spell danger. Cyanide compounds raise safety flags, especially in bulk production. Malononitrile itself isn’t as notorious as the cyanide salts you’d see in textbooks, but it still needs careful storage and handling. More than once, I’ve watched a lab partner handle it with extra-thick gloves and a nervous glance. Spills become a pain, and disposal asks for special attention.

Factories or research groups thinking about using malononitrile have to weigh the benefits against these headaches. Training and equipment cost money, and not every facility wants to invite cyanide risks through the door. If the process can’t justify the risk, they’ll often swap in something easier to handle, even if it means a longer or more expensive route to the final product.

Good chemistry isn’t just about knowing what a structure looks like; it’s about understanding what it lets you do and how you manage the risks. For malononitrile, that means engineers and scientists continue to look for smaller-scale, controlled methods to use or substitute it. Green chemistry pushes researchers to design processes that cut down hazards and waste, sometimes even finding new molecules that work similarly without the sharp edges of those cyanide groups.

Teaching new chemists about these risks—and the tightly coiled power inside simple structures like malononitrile—feels as important as any research breakthrough. Getting the balance right between innovation and safety keeps both people and progress moving forward.

Working with malononitrile isn’t something you take lightly. The stuff packs a punch—one whiff of its sharp odor can tickle your nose, but the real danger goes deeper. Malononitrile is toxic if inhaled or ingested and can soak through your skin, causing headaches, confusion, or worse. I’ve seen folks tempted to cut corners with chemicals that don’t look scary. That kind of thinking leads to close calls or ER visits, so I’m a stickler for doing things right from the minute I crack open a bottle.

The lab can feel safe, but fumes build fast in closed spaces. Always work under a fume hood—never just pop a cap open at a regular bench. I remember a time when a colleague skipped this step; we spent ages airing out the lab after alarms went off. The experience makes ventilation a must in my book. Good airflow keeps vapors from stacking up, protecting your lungs and keeping headaches at bay. If you can’t get to a hood, at the very least, open windows wide and set up a fan.

This isn’t the place for jeans and a t-shirt. Think gloves—nitrile or neoprene, not the thin latex kind. Malononitrile can creep through cheaper gloves in no time flat. Always grab a lab coat, preferably with long sleeves. Splash goggles save your sight from accidental sprays, and chemical-resistant aprons add another barrier. One time, a few drops landed on a friend’s arm, and even a short delay rinsing left a nasty red mark. Direct skin contact feels like fire, and it’s not worth the risk.

Malononitrile needs a secure, well-marked, and locked spot, away from heat and sunlight. Flammable cabinets work best—stuff it too close to acids or oxidizers and you’re courting trouble. I once found a cracked cap leaking fumes onto a shelf. Only regular checks and tight-sealing containers kept everyone out of harm’s way. Label everything clearly. Don’t let someone else mistake it for something harmless.

Spills demand instant action. Grab spill kits before starting work—don’t leave them in a back closet. If something tips, soak up the liquid with inert absorbents, slide it quickly into a sealed bag, and bin it with hazardous waste. Ventilate the room, alert others, and never try to sweep things under the rug. I’ve learned that a quick, honest report helps everyone stay safe; hiding a small incident invites bigger problems later on.

Wash hands and arms with soap and water every time, even if gloves never slipped. It’s easy to forget, but traces linger in odd places. Before you step out for lunch or home at day’s end, give your space a once-over. Keep eyewash stations and emergency showers clear and easy to reach. No equipment beats good habits—routine makes you ready for any surprise.

Sharing stories about mishaps and best practices builds a safety culture. Newcomers should get hands-on training, not just handouts. Safety isn’t just a rule; it’s a way to respect yourself and everyone around you. Malononitrile brings risk, but with care and attention, everyone walks away healthy and ready for the next experiment.

Science never feels satisfied with half-baked answers. The question on malononitrile’s water solubility pulls us straight into a world where chemical structure means everything. Malononitrile — a small molecule with a rather intense smell — brings two cyano groups attached to a central carbon. The presence of these -CN twins speaks volumes in a classroom and in a laboratory flask. Their electronegativity drags the central backbone toward a polarity water molecules easily recognize.

Let’s skip the jargon and focus on practicality for a moment. A lot of research and many industrial flows depend on whether someone can clean, dilute, or mix a compound in water. Malononitrile lands in synthetic chemistry as a building block, helping create pharmaceuticals, dyes, and resins. If it blends smoothly with water, everything from handling waste to making solutions for reactions gets simpler.

Yesterday, someone working in a university lab would test solubility not just from a textbook but by pouring a little powder in a beaker and stirring. Seeing it vanish, they move faster in their synthesis, because a water-soluble substance speeds up cleanup, reduces toxic residue in glassware, and gives a beginning chemist one less thing to fret over.

Malononitrile’s solubility sits around 133 grams per liter at room temperature. In plain terms, that's more than plenty. For such a small compound, these numbers blow past many household chemicals. This means if you drop a pinch into a glass of water and stir, the powder disappears. It hasn’t been forced to dissolve by heat or harsh shaking, it just does.

In real life, this trait has ripple effects. Environmental experts deal with the fallout when labs or factories dump waste. Water-soluble chemicals travel easily into streams and fields. Malononitrile isn’t classed as benign — it’s toxic, irritating, and potentially dangerous if mishandled. Easy movement in aquatic systems means disaster without proper treatment. Anyone running a process with malononitrile needs strong discipline, not just a bucket of water for cleanup.

Facilities handling malononitrile need strong safety routines. Water solubility helps in containment, because spills don’t linger like oil but dissolve and spread instead. Workers ought to respect this double-edged sword — easy mixing leads to rapid dispersal during an accident. Good gloves, goggles, fume hoods, and regular training keep everyone safer. A clear label and proper waste disposal signs don’t hurt anyone, either.

Some researchers look for substitutes that bring less risk during use or disposal. Not every reaction lets you swap building blocks easily, but some steps in chemical manufacturing can use greener chemistry with less toxic byproducts.

People talk about “chemicals” as if they’re strangers, but they shape the world, quietly or loudly. Malononitrile mixes with water because nature’s rules say electrons should tug and lock molecules together. This quirk makes life easier for scientists but harder for regulators and neighbors. Knowledge and respect for such properties, even in a single substance, shape the safety of every hand that ever opens a bottle in the lab.

Malononitrile is no everyday pantry item. It’s a chemical used mainly in labs and manufacturing, and it carries some real risks if handled wrong. Anyone who’s spent time working with it remembers the sharp smell and the way the bottle stings if it spills. Mistakes can have serious consequences, from health issues to surprise reactions, so careful storage is more than just a box to tick on a safety checklist.

People handling malononitrile deal with both toxicity and volatility. Breathing the fumes can spark headaches and nausea and, if you’re careless, much worse. It also breaks down under the wrong conditions, turning into things you don’t want floating around. Malononitrile reacts with bases and strong acids, sometimes heating up or releasing hazardous gases. Leaky containers or sloppy handling can turn a quiet shelf into an emergency.

Real safety starts with the container. Glass bottles with tight screw caps seem to last the longest. Plastics sometimes break down or react, so sticking with glass saves headaches later. Any label should be bold and clear, with emergency contacts and warnings in plain view.

Temperature lurks as a quiet but constant threat. Keep this chemical below room temperature—ideally around 15-25°C. Direct sunlight raises the risk of the liquid breaking down or pressurizing. Even a few degrees shift, thanks to a faulty AC or a sunny window, can ruin a batch or start a problem. In labs I’ve worked in, routines meant stashing the bottle at the back of the chemical store, away from sunlight and far from anything flammable.

Malononitrile hates moisture. If water sneaks into the bottle, the risk of hydrolysis jumps, leading to unwanted byproducts. Some labs keep small silica gel packs inside storage cabinets, giving that extra layer of defense against humidity, especially during those muggy summer months. In places with real humidity issues, a dedicated desiccator keeps things dry and stable—worth every minute of setup.

Many chemicals play badly together. Storing this compound close to oxidizers, acids, or anything strongly basic isn’t just careless; it risks an accident. Design the chemical storage so incompatible bottles sit on different shelves, or even better, across the room. Color-coded racks or simple barrier signs go a long way. A few years back, I saw a new technician line up everything alphabetically—until a supervisor stepped in to point out the real risks. Lessons stick best when they’re backed up by experience rather than reading from a manual.

No chemical lasts forever. Bottles that have sat too long often turn yellowish or start to crust over around the lid. Whenever that happens, disposal is the only safe move—using the right hazardous waste protocols, not just dumping it. Keeping a tight inventory helps, where every chemical gets a recorded arrival date and regular checks. This sort of diligence makes it less likely that something dangerous gets forgotten.

While malononitrile brings real hazards, smart routines control the risk. Reliable storage containers, temperature control, dry conditions, smart separation, and a strong checking system—these aren’t expensive changes, just common sense. Stories from experienced lab techs and old safety sheets both point the same way—chemical safety always starts at the shelf.

| Names | |

| Preferred IUPAC name | Propanedinitrile |

| Other names |

Propane-1,1-dinitrile 1,1-Dicyanoethane Malonodinitrile Propanedinitrile |

| Pronunciation | /ˌmæl.əˈnoʊ.nəˌtraɪl/ |

| Identifiers | |

| CAS Number | 109-77-3 |

| Beilstein Reference | 1209224 |

| ChEBI | CHEBI:16035 |

| ChEMBL | CHEMBL59139 |

| ChemSpider | 5464 |

| DrugBank | DB11363 |

| ECHA InfoCard | ECHA InfoCard: 100.003.195 |

| EC Number | 207-772-8 |

| Gmelin Reference | 60784 |

| KEGG | C00794 |

| MeSH | D008318 |

| PubChem CID | 8893 |

| RTECS number | OO1575000 |

| UNII | ERS96577G2 |

| UN number | UN2303 |

| CompTox Dashboard (EPA) | `DTXSID8020245` |

| Properties | |

| Chemical formula | C3H2N2 |

| Molar mass | 66.06 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | bitter almond |

| Density | 1.19 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.21 |

| Vapor pressure | 0.15 mmHg (20 °C) |

| Acidity (pKa) | 11.0 |

| Basicity (pKb) | 11.5 |

| Magnetic susceptibility (χ) | -23.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.385 |

| Viscosity | 2.25 mPa·s (20 °C) |

| Dipole moment | 4.09 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | S⦵298 = 189.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | ΔfH⦵298 = 72.6 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -1193 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS06, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H312, H315, H319, H332, H335 |

| Precautionary statements | P210, P261, P264, P271, P280, P301+P312, P304+P340, P305+P351+P338, P312, P330, P337+P313, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 3-2-1 |

| Flash point | 110°C |

| Autoignition temperature | 300°C |

| Explosive limits | Explosive limits: 1.7–5.5% |

| Lethal dose or concentration | LD50 oral rat 35 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Malononitrile: Oral rat LD50 = 55 mg/kg |

| NIOSH | MW8400000 |

| PEL (Permissible) | 3 mg/m3 |

| REL (Recommended) | 10 ppm |

| IDLH (Immediate danger) | 25 mg/m3 |

| Related compounds | |

| Related compounds |

Acetonitrile Succinonitrile Methylenemalononitrile Malonic acid Malonic anhydride |