The story of N-Butyronitrile, or butanenitrile, goes back over a century. Chemists searching for smarter ways to build carbon–nitrogen bonds identified it as a handy intermediate. This compound started as just another entry in thick chemistry catalogs, someone’s reaction vessel side product, but stubborn utility kept it in the industrial lineup. Early mid-20th-century chemical plants began producing it intentionally, not just as a byproduct of acrylonitrile reactions, but as a target for refinements, purity boosts, and easier handling. The further synthesis tech advanced, the sharper the focus on extracting N-Butyronitrile in higher yields using safer, cleaner processes, fitting the demand from agrochemical and pharmaceutical sectors.

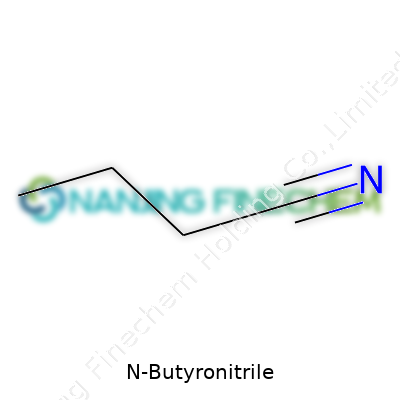

N-Butyronitrile presents itself as a colorless-to-pale yellow liquid, carrying a faint but unmistakably sharp odor familiar to those who handle volatile organics. Small container labels show a chemical formula: C4H7N, a simple string of four carbons ending in a nitrile group. Large drums of the stuff move through chemical depots worldwide, supporting projects from research synthesis to acting as a backbone in specialty chemical manufacturing. Even those who don't recognize the name have likely unwittingly encountered residues or breakdown products because of its broad industrial reach.

Consider N-Butyronitrile’s boiling point—117 °C—a midpoint that allows for manageable distillation without ultra-high pressures or cooling. The solvent-like ether odor often alerts lab hands to keep vials tightly capped. Density checks in at about 0.8 g/cm3, lighter than water, and it mixes well with organic solvents like acetone or ether, but keeps a frosty distance from most aqueous solutions. The molecule resists many casual attempts at oxidation or hydrolysis—its nitrile group won’t just break open for any watery or basic compound. Still, with strong acids and bases, or sustained heat, transformation can occur.

Suppliers catalog N-Butyronitrile with purities usually above 98%. Certificate of analysis provides not just purity, but details about refractive index (~1.391 at 20 °C), flash point (35 °C closed cup), and residue on evaporation. Drum and flask labels feature CAS number 109-74-0, hazard pictograms for acute toxicity and flammability, as well as statements like “Harmful if inhaled; avoid open flames.” Professionals don’t overlook these details—a misread label can mean a ruined batch or, worse, a hazardous situation in a tight laboratory or packed production floor.

Large-scale synthesis favors dehydration of n-butanol using ammonia and a catalyst, often at elevated temperatures around 400–500 °C, generating N-Butyronitrile along with water and minor byproducts. Historically, chemists also made it from 1-chlorobutane, swapping out chlorine for a cyano group through nucleophilic substitution using sodium cyanide or potassium cyanide. Such methods, while effective, draw heavy scrutiny—cyanides require rigorous containment and emergency protocols due to acute toxicity. Choice of method leans on the scale, safety requirements, and feedstock pricing, and any improvements tend to mean reduced risk or environmental impact.

N-Butyronitrile’s structure opens a path to an array of further syntheses. Reduction yields n-butylamine, an important intermediate for dyes and rubber chemicals. Acid or base hydrolysis pushes the nitrile group to a carboxylic acid or amide—n-butyric acid’s production stands as a classic transformation. Grignard reagents and organolithium additions forge new carbon–carbon bonds at the nitrile carbon. These reactivity notes move it from lab curiosity to necessity, driving innovations in pharmaceutical and materials research where what starts as N-Butyronitrile ends up in finely tuned molecules for targeting diseases or building block polymers.

Walk into a chemical storeroom and find a variety of names—N-Butyronitrile, 1-cyanopropane, butanenitrile, or butyronitrile—printed across bottles and safety sheets. Distributors may mark it as simply “Butyronitrile” or “1-Cyanobutane” on shipping manifests. The different names can confuse an untrained eye, but years of habit build the mental crosswalk between synonyms, avoiding mix-ups in stockrooms or ordering systems.

Workplace safety hinges on honest communication about N-Butyronitrile’s hazards. Short-term exposure through inhalation or skin can bring headaches, nausea, or even central nervous symptoms if mishandled. Flammable vapors mean strict demand for spark-free tools, isolation from heat, and well-planned ventilation. Containers get checked for leaks or corrosion, and Material Safety Data Sheets never collect dust near storage lockers. Labs and plants enforce tight spill containment, eyewash accessibility, and glove use—years in the business teach that a sloppy approach courts trouble.

N-Butyronitrile’s main traffic rushes through the corridors of pharmaceutical manufacturing, serving as a key intermediate in the sequence from simple molecules to active ingredients. Agrochemical synthesis counts on it, too, where its derivatives improve crop yields or combat pests. The material science world uses it to build precursors for plasticizers, rubber additives, and specialty polymers. In research, it supports custom molecule building, where chemists tweak substituents to chase performance in new materials or drug candidates. The product, then, makes itself present across both high-volume industry and cutting-edge custom syntheses.

Ongoing developments center on improving the safety, yield, and cost-effectiveness of N-Butyronitrile synthesis. Green chemistry drives efforts to swap hazardous cyanides for less toxic reagents or catalysts. Better process design has delivered continuous flow methods that slash operator exposure and environmental emissions. Research into downstream reactions—how easily N-Butyronitrile can be coaxed into amides, amines, or acids—feeds the pharmaceutical pipeline and keeps specialty chemical markets humming. Universities and industry teams keep probing new modifications, hoping their tinkering will bring more reliable performance, lower toxicity, or easier disposal.

Toxicologists look closely at both acute and long-term effects of N-Butyronitrile. High doses in animals can cause symptoms typical of cyanide poisonings, and evidence indicates some metabolic products can disrupt cellular function. Occupational health experts track air and surface concentrations in processing plants, seeking new monitoring techniques to catch leaks or unsafe work practices. Studies of wastewater and accidental releases nudge industry toward more careful treatment and recycling systems. Anyone working with N-Butyronitrile learns quickly that healthy respect for its hazards saves both lives and reputation.

Demand for N-Butyronitrile won’t disappear soon. The move toward greener processes shapes how companies approach its synthesis and disposal. Advances in catalysis offer routes that could knock down cost and cut waste. Some see promise in biocatalytic or enzymatic production, sidestepping hazardous reagents altogether. As regulations tighten on emissions, research teams keep exploring not just how to make and use this chemical, but how to do it with near-zero impact on workers and ecosystems. The compound’s flexibility, chemical simplicity, and wide application hint that it will keep earning shelf space for a long time, as both a workhorse of bulk chemistry and a cornerstone for new molecular designs.

N-Butyronitrile probably isn’t a name you hear at the dinner table, but you see it enough in the world of industrial chemistry. I remember walking into a manufacturing facility the first time, following a yellowed trail of chemical drums with cryptic names. N-Butyronitrile stood out since it doesn’t sound like something people would splash in their coffee. Folks use it for reasons that go deeper than just its odd smell—there’s real work done with this stuff.

Plenty of products begin life as chemicals you barely notice. N-Butyronitrile serves as a feedstock, which means it’s involved in kicking off the production of other things. Pharmaceuticals owe more to these chemical “middlemen” than people think. For example, some headache remedies use active ingredients built with the help of N-Butyronitrile. Chemists count on its structure to put together more complicated molecules, especially when making medicine or dyes.

Over the last decade, I’ve seen more companies use it for making crop protection agents, like pesticides or herbicides. Farmers chasing higher yields, or fighting off fungus, depend on new chemical tools. N-Butyronitrile helps set the stage for these solutions. Its role as a precursor in these areas links it directly to what ends up on supermarket shelves or in your fridge.

Polymers make up so much of modern life: car interiors, phone cases, fibers in clothes. N-Butyronitrile steps into play as a starting point for making specialty plastics. Acrylonitrile, a crucial material in the plastics world, partly comes from it. Without those building blocks, supply chains start to feel the pinch, and prices can climb for basic consumer goods. From what I’ve seen over the years, any hiccup with intermediates like N-Butyronitrile can mean delays everywhere down the line.

Anyone working close to this chemical knows you can’t take shortcuts with safety. It’s no friend to skin or lungs—exposure brings health problems. There’s a reason those drums look battered, but the safety labels always stay bold and clear. The solution here isn’t rocket science: proper storage, good personal protective gear, real oversight on transport. Tough regulations exist for a reason, and I’ve watched a few accidents happen when those standards get ignored just for speed.

Like a lot of chemicals in heavy use, N-Butyronitrile leaves traces and waste behind. Water treatment plants near chemical factories end up dealing with it. If companies cut corners, pollutants can slip into rivers or fields. Improved filters, updated treatment tech—these step up as ways to keep communities and workers safer. Some newer plants use “closed system” handling to cut down on leaks. From what I’ve seen, these shifts work best when pushed by both company policies and local watchdog groups who have a stake in their own backyard.

Most people never read the fine print on what fills a pill bottle or keeps bugs out of a tomato field. Many of these comforts start in a chemical warehouse with odd names like N-Butyronitrile. The stuff matters, and gets built into daily life, but a safe, responsible approach decides whether it’s a boon or a risk. Real progress in this corner of the chemical world won’t come from shortcuts; it comes when people actually respect the stuff they’re using.

N-Butyronitrile isn’t exactly a household name, but for those who work in chemical plants, labs, or factories, this colorless liquid demands respect. The stuff emits a sharp, almond-like odor, and that alone tells you that it’s not something to take lightly. I've spent plenty of hours on shop floors, and I’ve learned fast that ignoring chemical safety leads to problems nobody wants.

Contact with N-Butyronitrile can do real harm. Skin exposure causes irritation, redness, or sometimes even blisters. Inhaling vapors goes straight to your nervous system and can cause headaches, dizziness, or worse, breathing trouble. Swallowing it gives a swift reminder never to be casual around hazardous substances—vomiting, weakness, or even worse symptoms follow quickly. Reports show that this chemical gets absorbed fast, especially through the skin, so gloves and goggles aren’t just ‘nice to have’ items.

Most sites with N-Butyronitrile use mechanical ventilation or fume extraction to keep vapors well below dangerous levels. Opening a drum or pouring from a container? Workers swap jokes, but everyone checks their safety gear first. The sense of routine around gloves, face shields, and long sleeves keeps accidents rare. After a co-worker once skipped eye protection and paid for it with a near miss, nobody doubted the rules again.

Storing this chemical takes some attention. It belongs in tightly sealed containers, in a cool, dry spot, far from any heat source or open flames—because those vapors catch fire before you even realize what’s happening. The warehouse crew checks labels and locks up incompatible chemicals like acids and strong oxidizers in different spots. Mixing mistakes lay at the root of many industrial fires, and nobody wants a repeat.

Even with care, spills do happen. If you’ve got a puddle of N-Butyronitrile on the floor, it’s time for absorbent material—preferably something that won’t react—and plenty of ventilation. Large spills bring out the full team in breathing gear. The rules get drilled into everyone: never touch with bare hands, never hose it down a drain, never leave a spill unreported.

If somebody breathes in the vapors or gets splashed, speed matters. Remove contaminated clothing, wash skin for minutes, and head for medical help. Workplaces post emergency eye wash and showers, and most experienced hands keep the route clear in case someone panics.

Shifting chemical safety culture from box-checking to real care saves lives. Better labeling, updated training, and a habit of double-checking valves and transfers every shift take a little extra time. That effort goes a long way in keeping people safe. Some places have started looking at closed-loop systems to transfer and store N-Butyronitrile—less open handling, fewer risks.

People care about their coworkers, so sharing stories about near-misses helps. I learned more from old timers' tales than from any online module. Safety walks, regular equipment checks, and open talk when someone sees a hazard—those keep accidents from sneaking up.

Safe handling doesn’t mean living in fear, just working with respect for the risks. With N-Butyronitrile, as with any chemical, habit and good sense matter more than any sign on a break-room wall.

You run across N-Butyronitrile in a catalog, on a shipping label, or in a college chemistry lab, and at first glance it hides behind its simple name. Dig in a little, you find the formula: C4H7N. Four carbons, seven hydrogens, and a nitrogen. Nothing fancy in the structure, but those atoms team up to make a liquid with a sharp scent, often described as a little fruity and a little harsh. This particular molecule tends to show up behind the scenes, helping with things like making pharmaceuticals, pesticides, and solvents. In my own college days, the label N-Butyronitrile meant three things—gloves, fume hood, and respect. That formula speaks for itself, promising a reactive partner for making the next molecule on the list.

Molecular weight: 69.11 grams per mole. Sometimes chemists call it molar mass. This number tells you how heavy a single mole of those little C4H7N packets adds up to. It may sound like textbook trivia, but it matters a lot. If you ever stand in front of a balance, waiting for a readout to hit the mark, you rely on that number. You guess wrong, you mess up the entire reaction. At work, when I weighed out butyronitrile for a process batch, I always double-checked the math. Seventy grams looks light, but you throw it in the wrong tank or forget a decimal, and you either waste money or create a headache for quality and safety folk.

And about safety—numbers on a datasheet don’t always drive the point home. Bring N-Butyronitrile into a work area, and you smell it before you see it. It’s flammable. It won’t hesitate to irritate your skin and eyes. Inhalation can mess with your central nervous system. The same nitrogen that helps create pharmaceutical compounds can trigger headaches if you skip protective gear. I’ve watched even seasoned workers get surprised if they relax around these chemicals—everyone remembers the lesson a splash brings. Personal protection isn’t optional. Ventilation, gloves, and goggles stay on my checklist for a reason.

I’ve seen N-Butyronitrile act as a builder. It helps to stitch together carbon backbones for more complicated molecules. Chemical manufacturing plants use it to make things like pharmaceuticals and agrochemicals. Sometimes it gets blended into solvents, although very specific formulas use it because of its reactivity. In the research world, it sometimes pops up in synthetic routes—tools for building rings or linking weird branches the textbooks propose. I recall adding it dropwise to a round-bottom flask, watching the reaction change color, and feeling the weight of those numbers—one mole always meant 69.11 grams. No way around it.

If you look to the future, designing safer space and gear for handling nitriles remains a priority. Containment stops accidents. Doubled-up gloves, eye protection, and scrubbers for fumes cut down on injuries. Proper labeling prevents confusion. Tight rules about storage and disposal keep the spill team from earning their overtime. Chemists keep working on less toxic alternatives, especially for uses outside big production lines. Better training and clearer communication around these seemingly simple numbers—the C4H7N formula and the molecular weight—will spare both new and experienced hands a lot of trouble. Cold math, warm hands, and a sense of respect for the chemistry—that’s what keeps the lights on.

N-Butyronitrile sounds like something most folks never want to touch, and there’s some good reason for that. Like a lot of other nitriles, it’s clear, somewhat flammable, and smells a bit sharp—almost like almonds mixed with paint. Left in a spill, it turns the workbench into trouble fast. So, putting real attention into how this chemical gets stored doesn’t just tick a regulatory box, it keeps people safe and workplaces running without fire alarms or emergency showers getting involved.

Some warehouse managers want nothing more than to just stash chemicals wherever there’s space. But with N-Butyronitrile, cramped storage or plastic shelving won’t cut it. This liquid catches fire below the temperature of a summer day in Arizona. I’ve seen colleagues push drums into some unventilated nook, lights flickering above, thinking, “good enough.” It’s not. That’s how you end up with spontaneous vapor build-up and fire department visits.

Steel containers with tight-fitting lids make the safest homes for N-Butyronitrile. Keep it away from heat, sparks, flame, and anything that can generate static electricity. Cigarettes in your shirt pocket or cell phones lying around are risks too—this chemical takes no prisoners.

Throwing N-Butyronitrile next to acids or bases is asking for drama. Storage should always put distance between reactive chemicals. Folks sometimes overlook simple labeling. It sounds boring but matters every time a junior tech pulls something off the shelf. “Unknown clear liquid in a mystery jug” equals a disaster waiting to happen. OSHA and local fire codes both want bright, permanent hazard labels—no exceptions. They’re not just for show; these labels help the right people grab the right gear if an emergency shows up.

High heat or direct sun invites pressurization or slow breakdown, making the stuff even more dangerous. Frosty winters don’t treat N-Butyronitrile much better either; barrels that get too cold risk cracking. A dedicated chemical storage room, with a steady thermostat set around room temperature, pays off. No drafts, no stray sunlight. Windows covered. I’ve seen labs use cheap standalone sheds and then come to regret it after one storm.

Storing N-Butyronitrile in stale, dead-air rooms is a huge mistake. Leaks become silent creepers—vapor can build up until the air itself becomes dangerous. Fume hoods, proper air exchange, or even continuous low-speed fans help keep inhalation risks down. In my own experience, a stuffy corner storage area turned into a near-miss after someone ignored this simple fix.

Have spill kits, proper gloves, and emergency showers installed nearby. Running emergency drills sounds tiring, but panic in the moment makes everything worse. I’ve worked in shops that never practiced, and every time there was a spill, confusion reigned.

Keeping regulators off your back starts with following the Material Safety Data Sheet (MSDS) straight through. Don’t store N-Butyronitrile above shoulder height. Make it easy to grab a fire extinguisher—dry chemical, rated for chemical fires—not one of those cheap water sprayers.

Storing it right isn’t just about being cautious. It means fewer accidents, less wasted product, and peace of mind for anyone working nearby. Look past the fancy recommendations—real protection comes from sturdy shelves, solid containers, clear labeling, and learning from every near-miss.

N-Butyronitrile shows up on chemical order forms more often than most of us might expect. Folks in pharmaceuticals, agriculture, and specialty chemicals use it as a building block. Purity speaks louder than price in labs and factories. Typical industries keep an eye out for purities around 99% by gas chromatography, and some advanced uses push for better, up to 99.5% or more. That small difference makes for cleaner reactions and fewer headaches troubleshooting side products.

Chemists remember the frustration of traces of water or alcohols hung up in a bottle, creating ghost peaks and throwing off yield calculations. Even a simple research project on nitrile reactivity becomes a chore when a reagent isn’t as clean as promised. That’s why reliable suppliers publish a certificate of analysis, breaking down not only the assay but also the trace impurities that tend to stick around after distillation—things like moisture, aldehydes, or acids. Good suppliers test purity by GC and sometimes FTIR, and sell to companies that hold them accountable. Rubber manufacturers worry about metallic traces kicking off unwanted reactions. Those running multi-ton plants ask about stabilizers, as pure N-Butyronitrile has a habit of picking up acids over time, causing corrosion in steel drums or reactors.

In practice, nobody orders N-Butyronitrile by the spoonful. It’s sold by the liter or the ton. For the bench chemist, glass or HDPE bottles show up holding half a liter or a liter. These keep the liquid sealed, offer easy pouring, and tend to avoid the surprise of rust flakes if moisture sneaks in. Industrial buyers go for steel drums—180 kg or 200 L sizes come up most. These drums are lined or treated to fend off corrosion. Even with bulk delivery, most folks prefer drums, since upgraded tanks demand stricter safety measures and regular inspections.

A few large plants accept delivery by ISO tanks or road tankers. Here, you need strong infrastructure and safe offloading systems, since N-Butyronitrile gives off toxic fumes and carries some fire risk. Companies on tight budgets will stick with drums or totes, which balance shipping costs and inventory management. For smaller businesses, repackagers split drum-sized quantities into 20 L or 25 L pails, making it easier to handle by hand or with a cart.

Storing and shipping N-Butyronitrile never feels risk-free. I’ve seen shipping delays stack up because a label wasn’t clear or a drum leaked and set off alarms at a warehouse. The safety data sheet includes more red flags than most office chemicals, with clear advice on ventilation and flammability. Trained logistics teams know how to navigate hazmat paperwork and make sure everything’s labeled for easy traceability. Once, a supplier skipped moisture barrier liners and we opened drums that smelled like vinegar—a sign hydrolysis got started. Tight seals, dry storage, and regular stock rotation help dodge those surprises.

Global sourcing brings new headaches, especially when shipments cross borders. Customs agents care deeply about the chemical's intended use. Delays or confiscation can sink a project schedule if paperwork falls short or end-user declarations look wrong. Local regulations sometimes force repackaging, and that’s another chance for contamination. So some buyers press for regionally-certified suppliers.

People handling N-Butyronitrile think about safety, shelf life, and cost in the same breath. Newer packaging—like composite drums or improved closure systems—reduce the risk of leaks and cross-contamination. Training warehouse staff makes a real difference in safety and compliance. Chemical buyers smart enough to request a full impurity profile can spot problems before they land on the production line. It still pays off to ask suppliers tough questions about how they test, pack, and ship. Reliable purity and trustworthy packaging will always matter, and those lessons stick long after the invoice gets paid.

| Names | |

| Preferred IUPAC name | butanenitrile |

| Other names |

1-Cyanopropane Butyronitrile n-Cyanopropane Propyl cyanide |

| Pronunciation | /ɛnˌbjuː.tɪroʊˈnaɪ.trəl/ |

| Identifiers | |

| CAS Number | 109-74-0 |

| Beilstein Reference | 636086 |

| ChEBI | CHEBI:35840 |

| ChEMBL | CHEMBL149445 |

| ChemSpider | 8009 |

| DrugBank | DB14080 |

| ECHA InfoCard | ECHA InfoCard: 100.003.069 |

| EC Number | 202-457-0 |

| Gmelin Reference | 6766 |

| KEGG | C01791 |

| MeSH | D009995 |

| PubChem CID | 7736 |

| RTECS number | EK2975000 |

| UNII | Y14A3U5D88 |

| UN number | UN2349 |

| CompTox Dashboard (EPA) | DTXSID9020715 |

| Properties | |

| Chemical formula | C4H7N |

| Molar mass | 69.11 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Sweet, fruity, unpleasant |

| Density | 0.806 g/cm³ |

| Solubility in water | Moderately soluble |

| log P | 0.68 |

| Vapor pressure | 3.9 mmHg (20°C) |

| Acidity (pKa) | pKa ≈ 25 (α-H, DMSO) |

| Basicity (pKb) | 4.77 |

| Magnetic susceptibility (χ) | -19.6×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.393 |

| Viscosity | 0.423 mPa·s (at 20°C) |

| Dipole moment | 4.44 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 179.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -44.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3714 kJ/mol |

| Pharmacology | |

| ATC code | V09XX04 |

| Hazards | |

| GHS labelling | GHS02, GHS06 |

| Pictograms | GHS02,GHS07 |

| Signal word | Danger |

| Hazard statements | H225, H301, H311, H331, H319, H335 |

| Precautionary statements | P210, P261, P280, P301+P310, P304+P340, P311, P303+P361+P353, P305+P351+P338, P331, P370+P378, P403+P233, P501 |

| NFPA 704 (fire diamond) | 3-3-0-水 |

| Flash point | 38 °C (100 °F) |

| Autoignition temperature | 524°C |

| Explosive limits | Explosive limits: 2.6–10.7% |

| Lethal dose or concentration | LD50 oral rat 110 mg/kg |

| LD50 (median dose) | LD50 (median dose): 640 mg/kg (oral, rat) |

| NIOSH | WA8400000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of N-Butyronitrile: "20 ppm (70 mg/m3) TWA |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 200 ppm |

| Related compounds | |

| Related compounds |

Acetonitrile Propionitrile Valeronitrile Isobutyronitrile |