Adiponitrile didn’t just pop up out of nowhere—its story starts with the rapid push for synthetic fibers in the twentieth century. Scientists looked for replacements for natural materials, and the invention of nylon set off a race for new building blocks. Adiponitrile, an organic compound with the formula (CH2)4(CN)2, stood out for its role as a precursor to nylon 6,6. Back in the 1960s and 1970s, chemical giants shifted from time-consuming processes like dehydration of adipic acid oximes and electrohydrodimerization of acrylonitrile to catalytic hydrocyanation of butadiene. That switch came down to yield, safety, and the need to crank up global nylon production. Companies like DuPont and BASF steered the research, making adiponitrile a point of pride in their technical portfolios. To this day, that legacy shapes how the world makes versatile materials.

Adiponitrile is more than a mouthful—it’s a pale, oily liquid, and it holds the keys to some pretty important polymers. In most plants, it gets pumped out by the ton and moved around in dedicated tank cars or drums, since minor spills or leaks can mean big trouble. Commercial adiponitrile typically arrives as a high-purity liquid, pale or colorless, sometimes with a faint almond-like odor. The compound’s value climbs because it doesn’t just go into nylon—manufacturers also turn to it for specialty chemicals and intermediates in pharmaceuticals, coatings, and even batteries. Global demand closely traces the cycles of automotive and textile sectors since nylon persists in everything from seat belts to bristles.

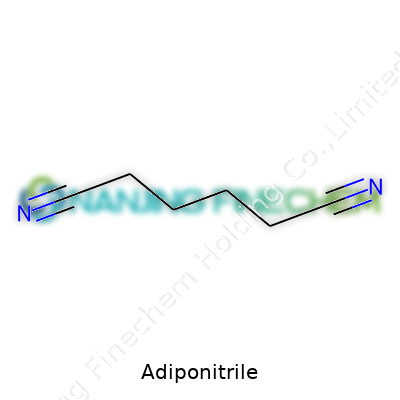

Folks working with adiponitrile know it as a liquid at room temperature, boiling near 295°C, and freezing around -2°C. It has a density of 0.97 g/cm3, making it slightly lighter than water, but not by much. Its high boiling point means it can hang around as a vapor if things heat up in a plant. Solubility skews low for water but rises for organic solvents like ether and acetone. Another feature—piloted strongly by those C≡N triple bonds at each end—lies in its reactivity with acids and bases, as well as its involvement in polymerization or further chemical transformations. Those nitrile groups lend some flexibility in synthetic routes, and they drive most of the compound’s chemistry.

Suppliers ship adiponitrile with clear technical sheets: purity usually not less than 99.9%, acid value below 0.01%, moisture below 100 ppm, and a color index that covers anything from water-clear to faintly yellow, depending on plant standards. Safety data sheets flag the CAS number 111-69-3. Hazards don’t get ignored—hazard pictograms for toxicity and corrosivity stand right on the barrel. It’s not just about satisfying international safety logistics, as any facility handling it needs to track its inventory by lot, production date, and supplier. Waste disposal data runs alongside to give operators what they need for safe storage and accident response.

Making adiponitrile started off as a technical headache, but engineers got better at it over decades. The classic route once ran through direct electrohydrodimerization of acrylonitrile—a mouthful for a process that used high electrical energy to stitch acrylonitrile into a six-carbon chain. As energy prices climbed, industry switched gears. These days, hydrocyanation of butadiene leads the field. A nickel-based catalyst brings butadiene and hydrogen cyanide together under controlled conditions, building up adiponitrile in high yields through consecutive cyanation steps. Some niche methods use alternative routes like amino-dehydrogenation or oxime dehydration, but economies of scale push most production into the nickel-catalyzed process.

Chemists treat adiponitrile as a starting point for big molecules. In one of the marquee reactions, hydrogenation batters those nitrile ends into primary amines, making hexamethylenediamine. That product partners with adipic acid to make nylon 6,6—a polymer that rivals steel for strength per weight, and ends up in zippers, machine gears, and many other spots. The nitrile groups also set the stage for further chemical modifications: reduction, hydrolysis back to acids, or cyclization to funky heterocycles used in advanced materials. Sometimes the molecule plays supporting roles in research—serving as an intermediate in pharmaceuticals or catalytic experiments that test new ligands and reactivity.

In the chemistry world, names always turn up variety. People call adiponitrile by its IUPAC name, hexanedinitrile, or simply 1,4-dicyanobutane. Trade names sometimes pop up, especially wrapped around proprietary blends marketed for specific industries, but in most technical parlance, “ADN” suffices. The compound was once known as tetramethylene dinitrile in older literature, so historical records sometimes paint a confusing picture for those chasing down material safety data sheets or import records. Different countries stick to their own naming conventions, but the backbone of two nitriles on a six-carbon chain keeps things clear.

Safety around adiponitrile means real vigilance. The liquid releases hydrogen cyanide if it encounters acids, and the fumes can turn deadly if ventilation falters. Operators need full personal protective equipment—gloves, goggles, face shields, and well-sealed suits. Risk of skin absorption and inhalation makes safety showers and closed-system loading the norm. Facilities hold fire protection standards high, swearing by grounding lines and regular leak inspections. Companies treat storage as a critical point: cool, dry, and away from heat sources, acids, or oxidizers. Spills require prompt hazmat response, with toxic vapor alarms and specialty foam. The industry follows strict regulatory standards pulled from OSHA, REACH, and EPA guidelines, so compliance checks run tight and regular.

Most adiponitrile flows directly upstream to hexamethylenediamine, and from there, right into nylon 6,6 plants. The demand in the plastics sector keeps entire chemical facilities busy, driven by car interiors, tire cords, carpets, and industrial textiles. Recent shifts in electric vehicles highlight a new niche: adiponitrile crosses over as an additive in lithium battery electrolytes, thanks to its stability and electrochemical compatibility. Some specialty coatings or resins use it for high-performance applications, sometimes as a bridge molecule or hardener. Its use in pharmaceuticals crops up in research, but less so on the industrial scale. As industries search for tougher, lighter, and more environment-resistant materials, demand for the compound rides along the global curve of innovation.

It’s hard to sit in a technology conference without hearing about greener, more efficient processes for chemicals like adiponitrile. Researchers dig into new catalytic systems to drop the toxicity tied to hydrogen cyanide, and plenty of chemists want to ditch nickel for earth-abundant alternatives. Some university teams experiment with fermentation-based synthetic biology—but making a six-carbon dinitrile biologically has yet to challenge the scale of current plants. Scientists also focus on improving selectivity and conversion rates to boost output without piling on waste. Better process monitoring and digitalization make newer facilities safer and less prone to batch errors. Next-generation applications, such as energy storage and advanced composites, push researchers to test modifications that could carve out space in emerging tech.

Every worker in an adiponitrile plant learns about its risks before stepping foot inside. The substance acts as a potent cyanogen—meaning that once metabolized, it can disrupt cellular respiration by releasing cyanide ions. In humans and animals, this causes headache, nausea, even fatal apnea at high exposures. Skin absorption or inhalation brings on the symptoms quickly. Chronic exposure over time links to mild neurological issues or skin irritation, though acute cases remain rare with modern controls. Researchers continuously monitor toxicity using animal models, seeking the threshold limits and best countermeasures. Exhaust ventilation, on-site antidotes, and strict worker health checks form the backbone of operational safety. Medical studies still track low-level exposure, aiming to tighten regulatory standards and update safety protocols.

The conversation around adiponitrile changes as industry grapples with decarbonization and tougher safety standards. Customers demand a cleaner supply chain. Technologies that cut hydrogen cyanide use or swap in renewable feedstocks stand out as game-changers, and chemical firms eye investments in digital plant control and waste minimization. On the application side, electric vehicles and renewable energy build more momentum for specialty polymer applications, making room for adiponitrile to shine in fields outside textiles. Scientists keep their eyes peeled for catalysts that work on a shoestring budget, hoping to reduce costs and meet stricter emission targets. The compound’s centrality to nylon and battery manufacturing promises to keep research intensive, and regulatory shifts across the globe have the power to pivot the market quickly. With the world moving faster, keeping a close watch on safety and innovation makes all the difference for those deeply connected to chemical manufacturing.

Most people don’t walk around thinking about chemicals with names like adiponitrile. Yet this tongue-twister sits at the core of modern manufacturing, slipping into our world through the clothes we wear, the carpets under our feet, and even under the hoods of our cars. Adiponitrile plays a starring role in making nylon 6,6, a material that pops up nearly everywhere.

Adiponitrile starts out as a clear, colorless liquid made through reactions with compounds like butadiene or acrylonitrile. What truly sets it apart shows up when it hooks up with hexamethylenediamine. Together, they become the base for nylon 6,6, a tough and versatile plastic found in textiles, tire cords, industrial belts, and automotive parts. Factories around the globe treat adiponitrile as a workhorse, pumping out millions of tons each year just to keep up with needs for sturdy, heat-resistant fibers.

Without this chemical, the textile industry would look much different. I remember growing up with those slippery, durable backpacks and windbreakers that lasted through many seasons. Nylon 6,6 helped shape that rugged world. The reason manufacturers chase this material comes down to its resilience—whether against heat or repeated stretching—and its ability to form strong, smooth surfaces. Adiponitrile doesn’t show up in the final fabric, but it’s hidden in plain sight behind the performance we’ve grown to expect.

No chemical like this comes without a set of challenges. The big worry with adiponitrile comes from how factories produce and use it. Manufacturing relies on some gnarly reactions and heavy-duty chemicals, including hydrogen cyanide, which carries real risks for both workers and the environment. I’ve watched towns wrestle with polluting industries, debating how much they’re willing to accept in order to keep the jobs coming. Cleaner methods—like electrocatalytic routes—offer hope, but replacing older ways takes investment and time. Some outfits look to bio-based feedstocks in order to cut down the carbon trail left by chemical giants.

Safety never feels like just a checklist. Mishaps in chemical plants can lead to dangerous leaks or fires, putting whole communities on edge. Tight regulation, up-to-date technology, and steady training go hand in hand to keep both workers and neighbors safe. It helps when companies open up about what they’re using and how they plan to keep waste under control. My own experience living near a manufacturing site reminds me that trust gets built not just on promises, but on transparency and action.

Once adiponitrile is turned into nylon, the story keeps rolling. Car makers depend on these fibers for parts that need to handle tough conditions. Clothing brands tout the durability of nylon, promising gear that stands up to adventure or daily use. Even in electrical engineering, nylon helps insulate wires and protect sensitive parts. This web of uses shows how one compound can spread its impact far and wide, far beyond anything you might expect from its cryptic name.

Folks in chemistry know adiponitrile as C6H8N2. Now, this may sound like trivia, but for people in industries far from a laboratory bench, that string of letters and numbers shapes plenty around you. That small combination—six carbons, eight hydrogens, and two nitrogens—unlocks the world of nylon. Nylon ropes. Bristles on your toothbrush. The seatbelt you buckle every time you drive. All of that starts with this one formula scrawled on a whiteboard.

You don’t usually see people get excited about synthetic molecules. But C6H8N2 carries more weight than you’d guess. Adiponitrile sits at the foundation of nylon-6,6 production. Factories around the globe pump this substance through industrial veins, transforming it with just the right tweaks, and soon you have fibers tough enough to hold a parachute and flexible enough for yoga pants.

What nudges this chemical into headlines is what it takes to make it. The usual path starts with butadiene and hydrogen cyanide, and cooks up a double-nitrile compound from there. Each molecule has that recognizable pair of nitrile groups—those CN in the formula—which stitch nylon monomers together. That process happens on massive scales, using lots of energy and plenty of hazard warnings.

Most people don’t spend their day worrying about nitriles, but I once toured a nylon manufacturing floor and watched men and women suited head-to-toe in incinerator suits, checking pressure valves, watching vats of chemicals bubble and steam. The formula C6H8N2 looks simple until you realize it must stay tightly controlled. Engineers monitor every step, knowing one small slip can spell disaster, not just downtime.

Noise from machines and a sharp chemical tang in the air drove home how jobs depend on this work. Nylon keeps manufacturers humming, from the American South to the industrial belts across Europe and Asia. That chemical formula goes from whiteboard scribble to job security for entire communities.

Environmental groups have sounded alarms over something like adiponitrile production. Factories put out greenhouse gases, risk toxic exposures, and demand a lot of water. In communities near chemical plants, folks want safe air and clean water. I’ve seen those local meetings, parents speaking up about headaches, or unusual odors after a late-night release.

Better solutions do exist. Cleaner production methods keep developing, like electrocatalytic synthesis, which trims down waste and keeps leaks in check. Companies have started investing real money in closed-loop systems, catching off-gas before it slips out into the world. Some researchers experiment with using alternative feedstocks, aiming to move away from the more dangerous raw materials.

So, C6H8N2 isn’t just a formula for chemists to memorize. It holds a slice of modern life—both the promise of progress and the costs that progress sometimes brings along. You don’t see adiponitrile on store shelves, but because of this molecule, the world around you gets stronger, safer, and a little bit more comfortable—if those making it and those living near it get a fair say in how it’s made.

Adiponitrile is a chemical with a funny name, but it’s the backbone of something many of us use every day—nylon. Almost every brush with this material, from clothes to car parts, ties back to adiponitrile. Creating it involves chemistry on a big industrial scale, which always brings in both opportunity and trouble.

Most factories don’t stick with one method forever. Over the years, two main processes have been doing the heavy lifting: the hydrogen cyanide route and the butadiene route. The hydrogen cyanide method, often called the hydrocyanation of butadiene, completely changed the landscape in the 1970s due to lower cost and higher yields. Plants take butadiene—made from cracking petroleum—and react it with hydrogen cyanide in the presence of special nickel-based catalysts. This dance of raw materials constructs the two nitrile groups required for adiponitrile, and creates fewer by-products than some older methods.

Before the shift, the electrohydrodimerization route had the spotlight. This one calls on acrylonitrile as a starting point and uses a whole lot of electricity to coax two molecules together, line them up, and stretch out the chain. It’s clever, and still sees some use today on a smaller scale, though the need for constant power and raw acrylonitrile means countries with cheap electricity or easy ingredient access are the main players here.

Where and how manufacturers choose to make adiponitrile affects the price of everything downstream. A hiccup at a plant in one country can send ripples across the planet, raising costs for folks making nylon jackets, medical devices, and even airbags. Global demand for nylon doesn’t slow down, so adiponitrile supply keeps markets tense. This has a way of stirring up trade spats, supply anxiety, and every now and then, short-lived price spikes that designers and automakers remember for years.

The elephant in the room with both major production routes: the handling of hydrogen cyanide. This is a compound that’s highly toxic, and no one wants it released outside of controlled spaces. Operators spend millions on sensors, tight process controls, and emergency response systems to avoid a leak. But the pressure doesn’t just come from safety officers. Today, activists and regulators in Europe and North America push for greater transparency, recycling, and reduced emissions during every step.

Some plants try to lower their environmental bill by recycling unused cyanide, switching to cleaner catalysts, and using renewable energy, especially in electric-hungry reactions. Still, progress comes slow, as redesigning an advanced chemical plant costs millions, and the temptation for shortcutting rules is real wherever oversight slips.

Young chemists and chemical engineers now look at adiponitrile and wonder if its future lies in biology. Biotech startups, especially those near major food and chemical hubs, press ahead with microorganism-based processes. Instead of volatile gases and hazardous intermediates, they promise fermentation vats with minimal waste and a dramatically lower carbon footprint. Industrial change tends to move at a crawl, as no executive wants to find out their shiny bio-process can’t deliver ton after ton at the needed price.

If labs manage a breakthrough, large-scale switchovers could one day cap off emissions and bring better job opportunities in places not tied to fossil fuel pipelines. Until then, most of the world’s adiponitrile will keep coming from the hard-hat, energy-hungry factories we know today.

I remember walking through the chemical plant for the first time, the sharp smell of solvents hitting me in the face. Adiponitrile isn’t as familiar to most people as gasoline or bleach, but it definitely has a reputation for being hazardous. Used mainly in nylon production, this stuff won’t offer a warning buzz before it causes harm. Eyes, lungs, and skin can all take a beating if things get sloppy in the workplace.

Breathing in adiponitrile vapors leads to headaches, dizziness, or worse: it can knock a person out and damage organs. Skin contact burns, and even a minor splash can cause serious irritation. You’d think this would make everyone respect it, but shortcuts pop up in busy plants. The tragic side of the story: major accidents have happened worldwide because folks cut corners on controls and personal protective equipment.

I’ve always relied on old habits for protection around this chemical. The most basic precaution is good ventilation. Pulling fresh air through the work zone and sucking fumes away at the source beats any fancy sensor. If you can smell something, or your eyes water, the system isn’t pulling its weight. Workers have collapsed from unexpected vapor clouds before, so air checks remain one of the most important pieces of the puzzle. Every site I’ve visited made regular air monitoring part of daily life, not just an annual event.

No one wants to suit up in bulky gear, but for adiponitrile, gloves resistant to chemicals, splash goggles, and lab coats make a massive difference. Contaminated clothing spreads danger far beyond the work area. At one site, I saw a worker carry traces onto a door handle, spreading rashes to half the crew. Quick-change gear outside the main plant and strict hygiene routines stopped problems like this from turning serious. Small acts—washing up, stashing personal gear separately, carefully labeling containers—add up to big safety wins over time.

Training happens on paper in many places, but knowledge really settles in when teams practice for emergencies. Would you know what to do if someone started choking or passed out? I’ve watched drills turn chaos into calm. Emergency showers and eyewash stations stood ready, and teams moved quickly. Waiting even thirty seconds to rinse in a chemical splash event can mean weeks of recovery.

Storing adiponitrile in snug, well-sealed containers is crucial. A leaky drum will eat through surfaces, or worse, find its way into drains. One lesson: keep it cool. Anything near a heat source raises pressure inside tanks, and that pushes vapors into the air. Proper signage and barriers came in handy during deliveries, keeping the wrong hands from accidently tapping into the wrong line.

Companies sometimes believe a fresh piece of equipment will fix safety. In reality, the right attitude carries more weight. Honest reporting of near-misses, strong team communication, and treating all chemicals with respect gets everyone home safely. I’ve watched seasoned operators set the tone for new hires just by noticing spills, fixing labels, or sounding the alarm when masks sat unused. That humble attention to detail: it turns complicated paperwork into simple, lifesaving habits.

Safe handling of adiponitrile isn’t about avoiding fines or ticking boxes; it comes down to refusing to let carelessness decide your future. Every warning label and glove turns into a statement about valuing your crew’s health. In the end, no shortcut is worth the price of pain, hospital bills, or regret.

Adiponitrile crops up mainly in the world of plastics, making nylon 6,6 possible. Industries treat it as a building block, a step toward fibers that end up in carpets, airbags, clothing, and even parts for vehicles. Despite its industrial value, the way companies ship, store, and use adiponitrile leads to questions about safety that don't go away simply because it's tucked away in factories most people never see.

People exposed to adiponitrile usually work with it directly. Most folks might never encounter it, but those who do stand at risk of inhaling its vapor or absorbing small amounts through their skin. Government agencies like OSHA and NIOSH have flagged it as a chemical that can mess with your body. Short-term exposure might bring headaches, dizziness, and nausea. Higher levels, even just for a short time, can lead to breathing problems and, in the worst cases, something as serious as cyanide poisoning. There’s a real reason for this: adiponitrile can break down in the body into substances that disrupt how cells use oxygen. That's not just uncomfortable — it's dangerous.

My own stint in a chemical facility taught me that PPE isn't just a suggestion. Gloves, goggles, and respirators went beyond protocol; they meant going home healthy. The most careful crew can still slip up, turning a routine day into a scramble for the eyewash station. It's not paranoia. The risk comes real, fast, if ventilation falters or a transfer hose leaks.

Factories don't always seal everything perfectly. Spills and leaks can send vapors into the air or trickles of chemical into soil and water. Adiponitrile doesn’t just vanish. It’s volatile in air and breaks down slowly, but while it lingers, it poses risks to fish and other wildlife. A fish kill downstream from a chemical plant almost always leads to finger-pointing, and chemicals like adiponitrile often end up in the spotlight.

Solid science, from EPA monitoring and journal reports, shows that even small leaks can build up over time. This isn’t just about rare accidents. Chronic, low-level pollution makes local communities uneasy. Living near chemical plants brings questions few can answer: Could my family get sick? Is the water safe to drink?

The industry's best defense starts well before anything leaks. Modern plants invest in closed systems and redundant sensors. Training stands front and center – you can’t fake knowing what to do in an emergency. A strict adherence to safety rules, regular equipment checks, and honest reporting of incidents help keep problems small. Neighborhood advocacy groups can play a big part, pushing companies and local agencies for full disclosure and tougher limits on emissions.

Switching to less hazardous alternatives makes sense, but companies rarely overhaul entire processes overnight. Instead, pushing for better containment, safer shipping practices, and stronger emergency planning can save both lives and landscapes in the short term. Worker health checks and real transparency about accidents offer the public some trust — a small bandage on mistrust that’s built up across generations of living near chemical industries.

Adiponitrile’s story fits into the wider tale of chemicals and community. Respect for its risks — and honest actions to manage them — goes much further than silence or secrecy. Once people see that, real progress feels possible.

| Names | |

| Preferred IUPAC name | hexanedinitrile |

| Other names |

1,4-Dicyanobutane Tetramethylene dinitrile Tetranitrile Tetramethylenedinitrile |

| Pronunciation | /ˌædɪˈpoʊnɪtraɪl/ |

| Identifiers | |

| CAS Number | 111-69-3 |

| Beilstein Reference | 1858733 |

| ChEBI | CHEBI:38456 |

| ChEMBL | CHEMBL14236 |

| ChemSpider | 8961 |

| DrugBank | DB11640 |

| ECHA InfoCard | ECHA InfoCard: 000026-62-6 |

| EC Number | 203-896-3 |

| Gmelin Reference | 74278 |

| KEGG | C06507 |

| MeSH | D003018 |

| PubChem CID | 8035 |

| RTECS number | AT3850000 |

| UNII | E6FDC3Z9XH |

| UN number | UN2205 |

| Properties | |

| Chemical formula | C6H8N2 |

| Molar mass | 108.14 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Faintly aromatic |

| Density | 0.96 g/cm³ |

| Solubility in water | 5.32 g/100 mL (20 °C) |

| log P | -0.35 |

| Vapor pressure | 0.37 mmHg at 25 °C |

| Acidity (pKa) | 11.1 |

| Basicity (pKb) | 15.2 |

| Magnetic susceptibility (χ) | -8.29 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.418 |

| Viscosity | 0.91 mPa·s (at 25 °C) |

| Dipole moment | 4.41 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 214.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -62.5 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3185 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS06, GHS07 |

| Pictograms | GHS02,GHS06 |

| Signal word | Warning |

| Hazard statements | H302, H311, H314, H317, H331, H411 |

| Precautionary statements | P210, P261, P280, P301+P310, P311, P330, P403+P233 |

| NFPA 704 (fire diamond) | 3-2-2 |

| Flash point | 85°C (closed cup) |

| Autoignition temperature | 410 °C |

| Explosive limits | 0.7–6.0% |

| Lethal dose or concentration | LD50 oral rat 100 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 100 mg/kg |

| NIOSH | PA1575000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Adiponitrile: "2 ppm (10 mg/m³) as an 8-hour TWA (OSHA) |

| REL (Recommended) | 4 mg/m³ |

| IDLH (Immediate danger) | 60 ppm |

| Related compounds | |

| Related compounds |

Hexamethylenediamine Adipic acid 1,4-Butanediamine Succinonitrile |