The chemical industry has always chased after molecules that make life easier for farmers, doctors, engineers, and factory owners. 3-Propylamine, often overshadowed by big names like ethylene and benzene, started showing up in labs around the years when scientists wanted to manipulate basic building blocks for bigger ambitions. Originally, folks working with amines began to see that simple tweaks to molecular chains let them push performance in everything from synthetic drugs to plasticizers. About the time organic chemistry gained traction in the last century, 3-Propylamine’s straight-chain skeleton offered chemists a direct route to explore a wild world of specialty compounds. I remember one old-timer mentioning that once, finding a clean route to this amine was a matter of competitive pride, with Russian, German, and American teams racing to patent methods.

3-Propylamine stands out as a colorless, fishy-smelling liquid that packs some punch because of its simple structure: three carbon atoms attached to an amine group. What drew me to it back in my college days was the way such a modest molecule could unlock so many doors in synthesis labs. In the market, it turns up as a raw material, priced based on purity, and something of a workhorse for anyone wanting to tweak amines without branching into more exotic chemistry. The four-carbon framework gives it enough flexibility without excessive steric bulk, so companies gravitate toward it for its reliability and broad usefulness.

Handling 3-Propylamine gives you a whiff of something almost metallic. Its boiling point sits near 48-50°C, so it wants to leap out of the bottle at room temperature, which always makes storage a challenge in humid or poorly ventilated spaces. The liquid flows easily and mixes well with water and many organic solvents, thanks to its polar nature. Solubility stands out as one of its strong points, giving process engineers a tool for fast, even reactions. It is flammable, reactive with acids and strong oxidizers, and it can corrode certain plastics and metals if left unchecked.

Suppliers usually sell 3-Propylamine in concentrations upward of 98% purity, with moisture and secondary amines kept below 1% to avoid downstream hiccups. Bottles feature the familiar UN number 1277, and safety labels scream “corrosive” and “flammable.” If you squint at the small print, you’ll see CAS number 107-10-8 and a decent run-down of chemical compatibility. I always check the certificate of analysis, since batch variation can spell trouble in precision synthesis, and small contaminants turn up in trace analysis of pharmaceuticals.

Most commercial operations use either reductive amination of propionaldehyde with ammonia, or direct alkylation of ammonia with 1-bromopropane and a strong base like potassium carbonate. It’s a dance between getting high yield and keeping by-products like dipropylamine at bay. Lab-scale methods can get fancier, but large-scale plants stick with what’s proven to deliver and slot into existing amine production lines. I’ve run both methods and found that tweaking temperature and solvent changes the by-product mix more than anything else. Large-scale distillation sorts out the rest.

3-Propylamine fits right into classic nucleophilic substitution reactions, thanks to its lone nitrogen pair. Once, I added it to an activated acid chloride and watched it cleanly form an amide—quick, reliable, and easy to purify. Chemists use it as a starting point for surfactants, herbicides, drug intermediates, and vulcanization accelerators for rubber. It also undergoes Schiff base formation with aldehydes and ketones, and forms complexes with metal ions, making it valuable in catalysis and analytical chemistry. Modifications usually aim to extend the chain, introduce functional groups, or tack on aromatic rings, letting each sector push performance without reinventing the entire process chain.

Walk down any chemical supply catalog and you’ll see 3-Propylamine sharing space with names like n-Propylamine, propan-1-amine, or 1-aminopropane. Sometimes you’ll even spot “propanamine” in older European papers. Each label essentially promises the same clear, slightly aggressive-smelling liquid, though branding can shift based on country or distributor. Even the paint and plastics industries have their own in-house trade names; I once saw a shipment labeled “aminopropane solvent” and only a tiny line at the bottom clarified it was 3-Propylamine. That kind of confusion keeps safety officers on their toes.

In any sensible lab, handling 3-Propylamine means working with gloves, goggles, and a solid fume hood. It burns easily, so it never belongs near open flames or hot plates, and spills call for quick absorbent action before vapors get ahead of ventilation. Its vapor can irritate eyes, lungs, and skin, so most places require shower and eyewash stations close by. The chemical’s reactivity with oxidizers and acids must guide storage: metal cans lead to rust, so the shift to HDPE bottles cut down on accidental spills. I’ve seen minor accidents where colleagues underestimated its potency—quick response made the difference.

Agriculture picked up on 3-Propylamine’s knack for boosting pesticide formulas or acting as a base for herbicide synthesis. In drug labs, it’s a stepping stone toward antihistamines and cardiovascular meds. Synthetic rubber makers reach for it when they want to fine-tune vulcanization speed. In specialty coatings and corrosion inhibitors, it acts as a flexible linker. Analytical chemists spot it as a reagent or buffer, mainly because it mixes well with a range of solvents and reacts predictably with most carbonyl compounds. Its versatility means you’ll find it in dozens of industries, each with their favorite recipe and trick for using its basic, lively chemistry.

As new molecules hit the market, chemists tinker with 3-Propylamine to unlock cleaner, safer, or more cost-efficient reactions. Teams across pharma, agrotech, and polymer science target it for building block status in custom molecules—especially as green chemistry grows in influence. The push for bio-based routes has moved some companies to look at fermentation or enzymatic pathways, hoping to bypass traditional petrochemical systems. Novel catalytic reactions, often designed to minimize waste or improve atom economy, keep labs busy, aiming to keep ahead of regulations and customer demand.

Animal studies and workplace exposure tests both point to moderate toxicity. Inhaling high levels brings acute irritation, coughing, and eye damage, so proper ventilation and masks aren’t just paperwork—they’re day-to-day essentials. Chronic skin exposure can sensitize workers. There’s ongoing focus—in both industry and academia—on making industrial process flows safer, and on finding better detection methods for accidental leaks. Toxicology data from trusted agencies reveals the amine can cause serious corrosion if given half a chance. I’ve fielded calls from chemists who didn’t see the immediate harm, but regretted ignoring long-term skin contact warnings.

Production keeps trending up as newer applications—like custom surfactants, smart polymers, and next-generation crop protectants—count on reliable feedstocks. Sustainable chemistry efforts motivate more teams to chase renewable, less polluting pathways, while automation promises safer plants and more consistent quality. Regulatory agencies keep a close watch, so the biggest advances might come from safer, more energy-efficient manufacturing methods or alternatives with lower toxicity. My hunch is that the next big leap comes not from the molecule itself, but from smarter ways of making, handling, and recycling it—a win for both bottom lines and public safety.

Mention 3-Propylamine to most folks and you’ll probably get a blank stare. This isn’t some household staple or trending buzzword; it’s a colorless liquid with a fishy smell that most people only encounter in textbooks or chemical supply lists. Despite that, its role in daily life can’t be brushed aside. From my vantage point in the world of chemistry, I see it as a quiet workhorse—one that rarely gets the spotlight but never stops moving materials, reactions, and ideas forward.

Let’s face it—without small-chain amines like 3-Propylamine, everything from medicine to materials science would stall out. In the lab, you often run into it during the building phase of bigger, more complex molecules. You’ll find it serving as a base, starting conversations between other chemicals to create new, more useful products. The neat thing about 3-Propylamine: its simple structure makes it highly reactive. That trait keeps it in the toolkit for chemists hoping to make pharmaceuticals or pesticides. It’s like having flour in a baker’s pantry; it forms the backbone for things nobody even thinks about twice.

Walk into a pharmaceutical lab, and you’ll notice shelves lined with screw-top bottles, some of which hold building blocks like 3-Propylamine. Several medicines trace their lineage back to reactions involving this amine. It’s a piece in the puzzle for antihistamines and certain antidepressants. Drug makers rely on it as an intermediate—yes, a stepping stone that helps them piece together the active ingredients in tablets or injectables found at your pharmacy.

Agriculture leans on this same molecule, though for a different crowd of chemicals. You wouldn’t eat it directly, but plants sure benefit when it helps manufacture herbicides and insecticides that farmers apply to keep crops healthy. It indirectly impacts what ends up on store shelves and, eventually, your dinner plate. Food supply security might seem like a stretch for a smelly liquid few people recognize, but it all connects behind the scenes.

On the industrial side, factories use 3-Propylamine to whip up rubber additives and corrosion inhibitors. These products make sure car tires last longer and pipelines don’t rust out before their time. I’ve seen factories pumping out items we all use—garden hoses, grips on tools, gaskets for cars—rely on processes that quietly require this chemical. Even in the world of dyes, 3-Propylamine can help deliver certain pigments, which make your clothes bright and bold.

Any time chemicals like this get tossed around, safety should get some attention. 3-Propylamine carries risks both in production and use. Inhaling it feels rough—strong odor, possible respiratory irritation, and a serious need for protective gear. There’s always a balance between ramping up production to meet demand and keeping workers safe. Companies with tighter safety protocols usually see fewer accidents. It’s not glamorous, but updating training programs and investing in personal protective equipment can cut down on risks. Regulators keep an eye on emissions and workplace practices, but real change comes from companies prioritizing health and transparency.

Chemistry often finds itself at a crossroads: keep expanding and risk environmental fallout, or invest in research to stay sustainable. The pathway forward includes recycling solvents, using renewable feedstocks where possible, and developing less hazardous alternatives. Research teams look for ways to reduce toxic byproducts, aiming for processes that protect both people and the planet.

In the end, 3-Propylamine might seem unremarkable, but it touches lives in ways most never notice. Keeping its use both productive and safe demands steady improvements—something we all stand to benefit from whether we realize it or not.

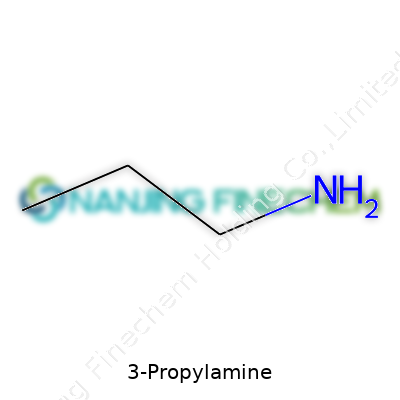

Nobody wakes up excited about a chemical formula, but step into a lab or a factory, and these combinations of letters and numbers start making a lot more sense. Let's look at 3-Propylamine. Its formula is C3H9N. That's three carbon atoms, nine hydrogens, and a nitrogen. Not hard to remember if you sketch the thing out. There's a straight chain of three carbons—no funky loops or extra branches—ending with an amine group (that’s the -NH2 tag at one end).

Draw it out, and you'll see: CH3-CH2-CH2-NH2. That's what the structure looks like—propyl connected to an amine. This simple layout gives 3-Propylamine some interesting properties that deserve attention, especially if you’re handling chemicals in the real world.

Three carbon atoms in a row with nitrogen at the end doesn’t set off alarm bells, but it matters a lot to folks working with amines every day. Straight-chain amines, like 3-Propylamine, find use in the creation of drugs, surfactants, and even agricultural chemicals. The amine end grabs on to other molecules in a reaction, which means chemists use this compound as a building block for more complicated products. It’s not some rare, exotic molecule—just useful and reliable.

Walk into a small-scale lab, and 3-Propylamine shows up as a colorless liquid with a sharp, ammonia-like odor. Anyone who’s spilled a bit on their gloves knows the smell lingers. It’s also flammable. The simple structure makes it easier to synthesize, and it reacts pretty predictably in standard organic reactions, easing the work for chemists designing new compounds.

It’s not all building blocks and sweet-smelling success. I remember my first week in a synthesis lab—nobody warned me about how fast the fumes of 3-Propylamine can burn your nose and eyes. Too much exposure, and you’re not just coughing; you risk more serious irritation or worse. The nitrogen atom in 3-Propylamine forms hydrogen bonds, so it’s easily picked up and carried through air or water. Proper ventilation and gloves aren't just advice. They keep people safe. Even if it feels like a minor compound, respect it.

Beyond the irritation, there's worry about long-term exposure. Papers from occupational safety groups show amines like this one can cause problems if handled carelessly. Industrial settings often require training and strict procedures—no shortcuts. I learned to double-check labels and lids after one rushed morning. A little care means fewer headaches—literally and figuratively.

I’d like to see more attention on greener synthesis routes. Right now, petroleum-based precursors remain standard, though researchers hunt for plant-based alternatives. Updating equipment in older plants, ensuring workers get real safety training, and investing in technology to capture or neutralize emissions would help cut incidents and health risks. Replacing outdated protocols might cost upfront, but it stops bigger problems later.

Beyond industry, it helps to demystify simple molecules like 3-Propylamine for students labs and small companies. Chemistry depends on attention to detail—and understanding one small molecule often opens the door to broader creativity, safer practices, and more responsible use of what we make.

Walk into any facility where chemicals play a part, and you’ll hear stories about near misses. 3-Propylamine brings its own set of dangers, and ignoring safe storage is asking for trouble. This stuff gives off vapors that sting the nose and eyes, and just a small leak can cause headaches or worse. Anyone who’s spent time in a lab, warehouse, or manufacturing plant knows that a simple mistake can snowball if you don’t respect what you’re working with.

A drum of 3-Propylamine stashed in a broom closet spells disaster. This chemical thrives in the shadows, away from sunlight and heat. Stick it in a cool, dry place with good airflow. Treat its container like a bank vault—sealed all the way, no cracks, no buckled lids. If it leaks, those fumes rush out fast, and suddenly everyone’s coughing or worse. Metal can corrode, so a plastic drum with a tight cap often outlasts the rest.

Far too many accidents start with the wrong containers. Polyethylene works well because it doesn’t rust out or react with the amine. A single rusty lid or weak gasket invites leaks. Keeping 3-Propylamine separate from acids and oxidizers is not some bureaucratic hurdle—the smoke and heat from an accidental mix make one hell of a mess, and local fire crews have enough on their hands.

Handling means more than pouring from barrel to beaker. Splashing some on your skin might not seem serious in the moment, but that burning sensation lingers. Gloves aren’t just for show; they stop contact and save hours in the emergency room. Goggles spare your eyes from agony. Those clunky aprons keep spills from soaking your jeans.

Breathing easy around 3-Propylamine doesn’t happen without a plan. It reeks, and those fumes hang heavy without proper ventilation. A plain exhaust fan above the workbench cuts the risk. Spills shouldn’t trigger panic if there’s a protocol: absorb with kitty litter or sand, then sweep it up into a safe waste bin. Water makes things worse by spreading the chemical, not cleaning it.

Mistakes with 3-Propylamine can lead to fires, burns, and chemical spills that last far beyond the work shift. Back in college, a buddy of mine lost part of his thumb to a splash. He wore gloves but skipped the apron. Nobody forgets that lesson. People protect each other by reading the label, checking the storage area, opening windows, and making sure spill kits aren’t just collecting dust.

OSHA and EPA rules aren't there for paperwork; they’ve come from decades of trial and error. Regular safety checks, staff training, and easy-to-read signage do more than tick a box—they stop the accidents before they start. Storing flammable chemicals far from ignition sources isn’t just wise, it’s basic common sense. Fire extinguishers, eye wash stations, and emergency showers need to stay ready and visible.

A workplace that treats 3-Propylamine like just another bottle on the shelf winds up on the front page for the wrong reasons. Storing it cool and dry, labeling every drum, and triple-checking containers before each use keeps more people safe. Safety meetings every month, real drills instead of lectures, and looking out for each other builds trust and keeps hands, eyes, and lungs intact. That’s the kind of culture where nobody has to learn the hard way.

The name 3-Propylamine looks technical on paper but the stuff inside the drum brings real-world concerns. This clear liquid carries an ammonia-like odor that sends most people stepping back from the barrel, and for good reason. A little reading reveals it’s part of the amine family, chemicals often used by folks in everything from pharmaceuticals to rubber production. But sniffing too close or splashing skin isn’t pushed aside as “just another workday.” Safety sheets for this stuff practically shout about its health risks.

Take a whiff of 3-Propylamine and you’ll know it’s not meant for breathing in. After some years in labs and around chemical storage, the reminders don’t fade—pick up an ammonia knockoff and coughing, watering eyes, even headaches can flare up in seconds. Inhalation of low concentrations stings the nose and throat. Higher doses set off dizziness, chest tightness, and in some cases, it makes breathing feel heavy. Some chemicals just irritate airways, but amines like this one dig deeper, working their way into the lungs and eyes faster than most expect.

Skin doesn’t come away unscathed, either. Even a splash burns. I’ve watched gloves fail where someone thought a splash guard was overkill. Within minutes, redness, pain, and chemistry’s version of a sunburn line started to show. Eyes suffer even worse. Direct contact usually means immediate medical attention, because damage can stack up quickly—imagine inflamed, tearing eyes that can’t seem to find relief. According to the U.S. National Library of Medicine, repeated exposure can cause dermatitis and deeper tissue injury, not just a little redness at the site.

It’s fair to ask how toxic it truly is—the answer isn’t comfortable. The median lethal dose for rats (LD50) sits around 570 mg/kg orally, which qualifies it as dangerous if swallowed. This isn’t cyanide, but it lands higher on the toxicity charts than many household chemicals. For anyone handling bulk containers or using it daily, cumulative effects stack up—chronic exposure can affect the nervous system and liver, based on cases in occupational settings. The Centers for Disease Control and Prevention notes that vapors irritate respiratory systems, and the liquid’s damage to mucous membranes isn’t reversible after enough time or exposure.

Working around 3-Propylamine never feels routine—ventilation, gloves, sealed goggles, and careful handling aren’t overdoing it, they’re just common sense. The reality is, once a chemical lands on “dangerous” lists, people can’t rely on instincts or tough-it-out approaches. Instead, safe use in factories and labs comes down to training, strong safety gear, and real respect for chemistry’s bite. Emergency showers and eyewash stations close by aren’t just extra—they’re life-savers on bad days.

In smaller companies and old-school labs, there’s temptation to cut corners or treat warnings as checkboxes. Building a culture where everyone watches out for slips and takes PPE seriously isn’t cheap, but it’s miles better than firefighting after an accident. Switch to alternative chemicals where possible, invest in real ventilation, and run regular safety drills. Health and safety rules exist for hard-learned reasons—every chemical hazard that’s ignored usually ends up proving its point. 3-Propylamine doesn’t give second chances to those who underestimate it.

Chemicals like 3-Propylamine deserve more attention than a dry list of numbers in a safety sheet. Anyone who’s stepped into a lab knows how much character even simple molecules have. 3-Propylamine, also known by its tongue-twisting name propan-1-amine, catches the eye for reasons beyond its structure. At its heart, it’s a colorless liquid, and you’ll catch a whiff of ammonia if you get too close—nothing subtle there.

Boiling point shows up more often than expected, especially in real lab work. For 3-Propylamine, it clocks in around 48 to 49°C—noticeably lower than room temperature on a summer day in many parts of the world. That might sound technical, but anyone who’s tried to store or transfer this stuff knows the unique set of challenges this brings. Rapid evaporation means that spills don’t stick around, but the strong odor travels fast and can make a whole room pretty uncomfortable.

Compare that boiling point to water at 100°C, and it’s obvious why labs need solid ventilation and tight storage. It’s volatile, and its vapors love to spread. In my own time working next to a fume hood, nothing gets your attention faster than a reminder from your nose that you left a bottle open too long. The low boiling point pushes everyone to rethink handling strategies, not just for safety but for loss of the chemical itself.

Physical characteristics often slip through the cracks in discussions, but ignoring them comes back to bite. 3-Propylamine stays as a thin liquid, which means it pours quickly and doesn’t cling to surfaces—a blessing and a curse. On one hand, cleaning up is faster; on the other, leaks run rampant if a seal fails. It mixes well with water, behaving like most small amines, so there’s little issue blending it into mixtures. The flip side is that aqueous spills are tough to separate, and contamination happens fast.

I’ve run into that exact problem during synthesis prep. A seemingly minor container crack, unnoticed for a day, led to a sharp stink and a lot of wasted material. Even tracing the leak wasn’t straightforward, since 3-Propylamine wicks through paper towels and gloves with impressive determination.

This compound doesn’t just evaporate easily—its vapors catch fire quickly, too. The flash point hovers below room temperature, often around 0°C, so it isn’t enough to just keep it capped. Every move demands respect for its flammable nature. I’ve watched new students fumble through container transfers, unaware that static alone can spark a nasty accident. Good protocol means grounding vessels and using blast shields, even for what looks like a small, harmless amount.

Manufacturers know the score: proper handling gear, flame-proof cabinets, and routine checks aren’t options, they’re daily habits. Facilities that stay sharp on these protocols prevent headaches and, at worst, disasters.

Working with 3-Propylamine gets much smoother by controlling temperature, keeping containers airtight, and sticking to regular checks. Simple tricks, like cold storage and using absorbent liners in storage bins, go a long way. Emphasizing ventilation, even in older labs with patchwork systems, makes a difference. And having a backup plan for spills keeps panic at bay.

It’s not only about recognizing its quirks but respecting them—these habits keep the workplace safe, productive, and a lot more pleasant to work in.

| Names | |

| Preferred IUPAC name | propan-1-amine |

| Other names |

Propylamine 1-Aminopropane n-Propylamine n-Propyl amin |

| Pronunciation | /proʊˈpɪl.əˌmiːn/ |

| Identifiers | |

| CAS Number | 107-10-8 |

| 3D model (JSmol) | `C3H9N` |

| Beilstein Reference | 1718738 |

| ChEBI | CHEBI:50385 |

| ChEMBL | CHEMBL16236 |

| ChemSpider | 71977 |

| DrugBank | DB04111 |

| ECHA InfoCard | ECHA InfoCard: 100.003.933 |

| EC Number | 202-810-2 |

| Gmelin Reference | 8086 |

| KEGG | C01510 |

| MeSH | D016581 |

| PubChem CID | 12046 |

| RTECS number | UB0700000 |

| UNII | V4X3T5YCD8 |

| UN number | UN1277 |

| Properties | |

| Chemical formula | C3H9N |

| Molar mass | 59.13 g/mol |

| Appearance | Colorless liquid |

| Odor | Ammonia-like |

| Density | 0.741 g/mL at 25 °C (lit.) |

| Solubility in water | miscible |

| log P | 0.23 |

| Vapor pressure | 3.7 kPa (at 20 °C) |

| Acidity (pKa) | 10.6 |

| Basicity (pKb) | 3.38 |

| Magnetic susceptibility (χ) | -6.1×10⁻⁹ |

| Refractive index (nD) | 1.387 |

| Viscosity | 0.46 mPa·s (20 °C) |

| Dipole moment | 1.33 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 242.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -48.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4686.7 kJ/mol |

| Pharmacology | |

| ATC code | N06AX10 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02, GHS07, GHS05 |

| Signal word | Danger |

| Hazard statements | H226, H302, H314 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P264, P280, P303+P361+P353, P304+P340, P305+P351+P338, P311, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 1-3-0 危 |

| Flash point | 43 °F (6 °C) |

| Autoignition temperature | 430 °C (806 °F; 703 K) |

| Explosive limits | 2.1% - 10.4% |

| Lethal dose or concentration | LD50 oral rat 820 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 820 mg/kg |

| NIOSH | PC9285000 |

| PEL (Permissible) | PEL: 8 Hr TWA 500 ppm (1200 mg/m³) |

| REL (Recommended) | 150 ppm |

| IDLH (Immediate danger) | 700 ppm |

| Related compounds | |

| Related compounds |

2-Propanamine 1-Butanamine 3-Aminopropanol Propylamine hydrochloride n-Propylamine Isopropylamine |