During the surge of organic chemistry research in the late 19th century, labs started tinkering with various amines, hoping to find new ways to tailor basic chemicals for industrial use. 2-Ethylamine emerged as researchers looked for small, versatile molecules that could serve as both starting points and connectors in bigger syntheses. The compound became a staple in both European and American chemical manufacturing by the mid-20th century. Early methods relied on harsh conditions, but over decades, techniques softened, yields improved, and industrial settings began to pay closer attention to worker health and atmospheric emissions. Today, 2-ethylamine is produced with an eye not just for efficiency, but for careful stewardship of resources and the planet.

This amine shows up as a clear, highly flammable liquid with a strong, fishy odor. It boils at about 36°C, so it evaporates easily at room temperature. 2-Ethylamine mixes well with water and common organic solvents, thanks to its small size and high polarity. In my old lab days, the containers would steadily lose volume to evaporation, unless tightly capped and kept cool. Chemically, it’s a good base, readily grabbing protons from acids, and quick to form bonds with all sorts of carbon-containing molecules. If you spill a bit, the smell lingers, and the vapors bite at your nose and eyes—not something you forget after a long synthesis shift.

Manufacturers bottle up 2-ethylamine with careful labeling, since a mix-up with other amines can spell disaster for both process and safety. Commercial supply typically requires a minimum purity of 99%, water content below 0.1%, and freedom from heavy metals. Most drums carry hazard pictograms and bold warnings to avoid skin or eye contact. Aerospace, pharma, and chemical plants scrutinize these labels because a batch with even a small impurity can cause a failed reaction, or worse, a catastrophic byproduct.

To create 2-ethylamine, most plants react acetaldehyde with ammonia, either in the vapor phase or by high-pressure liquid processing. Catalysts—often based on nickel—speed up the conversion and keep yields high. Throughout the process, plant operators need to keep a close watch on temperature and pressure. Pushing things too hot or too hard gives unwanted side reactions, and the resulting waste can corrode equipment or harm local waterways. Many chemical companies now recover waste heat and recycle leftover reactants, turning what was once a single-use system into a nearly closed loop.

What makes 2-ethylamine valuable isn’t just its structure, but its eagerness to react. It forms strong bonds with acids, giving amides and imides. It also joins up with aldehydes and ketones, forming imines—essential ingredients for making dyes, pharmaceuticals, and agrochemicals. The ethyl group gives it a touch of steric bulk, so you can coax out selectivity in reaction pathways, avoiding unwanted attachments. In the hands of a skilled chemist, it unlocks more possibilities than many other small amines. Over the years, I've seen it help build anti-seizure medications, advanced coatings, and herbicide intermediates, all thanks to that delicate mix of reactivity and stability.

The chemical world loves synonyms, and 2-ethylamine goes by a few: Ethylamine, monoethylamine, and sometimes MEA in shorthand, though confusion can arise with monoethanolamine, a different compound. Trade catalogs also list it under a range of product codes depending on supplier. A new buyer can spend half a day sorting through names before landing on the right drum for their synthesis. In a global supply chain, tight technical data ensures that everyone’s talking about the same stuff, regardless of language or acronym soup.

Handling 2-ethylamine, forget gloves or goggles at your peril. The vapors sting your eyes, irritate lungs, dry out skin. Safety data sheets and plant guidelines hammer this home, insisting on closed systems, exhaust hoods, and emergency showers. Spills and leaks don’t just cost money, they present real health risks to workers and the environment. In regulated industries, periodic training, personal exposure monitoring, and continuous airflow checks keep the workforce out of harm’s way. I've sat through plenty of these safety briefings—boring, maybe, but a small price for protection when accidents carry lifelong consequences.

2-Ethylamine serves as a workhorse in many sectors. Agriculture companies use it to build up next-generation pesticides and growth regulators. Pharmaceuticals depend on it for constructing specialized drugs, especially those where a short, polar “handle” on the molecule speeds up metabolic entry. Dye and pigment manufacturers value its reactivity and color-fixing abilities, while specialty coatings use its base strength and volatility for unique hardening cycles. In the energy field, it occasionally pops up as a scavenger for unwanted acids and reactive impurities. Whether it’s farm, factory, or pharmacy, this simple amine proves indispensable.

Labs worldwide keep searching for new ways to stretch what 2-ethylamine can do. Researchers are tweaking synthesis methods to slash waste, improve yields, and cut greenhouse emissions. In pharma, chemists probe its use in building novel therapeutic agents for everything from cancer to neurological disorders. Dye chemists have found it gives richer, longer-lasting colors when skillfully applied to synthetic fibers. I've come across patent filings for bio-based production routes that could bypass petrochemicals, promising fresher air and lower bills. Behind the scenes, academic groups and start-ups jockey to push this core chemical into uncharted territory.

Toxicity remains a real concern with 2-ethylamine. Acute exposure causes burning, headaches, nausea. Long-term or high-dose contact damages eyes, skin, and can stress the liver. Regulatory agencies like the EPA and ECHA watch over its use, setting strict exposure limits and disposal rules. Medical research has examined whether it builds up in living tissue, and so far, biomonitoring shows it gets processed and excreted efficiently. Still, animal studies signal caution—chronic exposure stresses bodily systems, and plant workers need regular health checks. In my career, I’ve seen process improvements driven alike by compassion and regulation, both working to cut accidental exposure to near zero.

The horizon for 2-ethylamine looks busy. Demand for specialty chemicals points toward rising production, but with ever-tighter rules on emissions and worker safety. Companies are investing in greener synthesis, advanced automation, and smarter containment systems. Pharma and ag fields call for fine-tuned amines with minimal impurities, driving both purification tech and molecular analytics. On the research front, lignin and algae-based feedstocks might eventually feed 2-ethylamine reactors, breaking the old link to fossil carbon. My bet: the next decade brings not just more of this molecule, but cleaner, safer, and more creative ways to put it to work.

If you’ve ever wondered how flexible foam ends up in your couch, or what helps keep crop yields steady in unpredictable weather, there’s a good chance 2-Ethylamine played a role somewhere down the road. Sometimes, the most important workers keep the quietest profile. That’s the case with this clear, pungent liquid that quietly supports much bigger stories in manufacturing and agriculture.

2-Ethylamine steps in early during the crafting of polyurethane foams. Manufacturers rely on it as part of the toolkit to fine-tune the foam’s bounce and firmness. This foam shows up in mattresses, cushions, and even steering wheels. A production line can’t simply swap it for anything else without sending material costs up or risking a dip in comfort. Polyurethane’s flexibility owes a fair bit to this underdog chemical.

I’ve spent a few years watching how farms gear up for spring. One of the challenges is protecting seeds from disease before they break soil. 2-Ethylamine works as a building block in some crop-protection products. Chemists put it through a series of tweaks and reactions to make herbicides and fungicides that shield crops when they’re most vulnerable. Without chemicals like these, farmers face lower yields just when feeding a growing world gets trickier every year.

The pharmaceutical sector also taps 2-Ethylamine as a starter for producing active ingredients. Some antihistamines and heart medications come together thanks to careful use of this chemical. It acts as a handy starting point for building more complex molecules. Drugs that keep allergies at bay or support blood pressure sometimes carry a bit of its chemical backbone with them.

Walk down the aisles of any workshop supply store, and the bottles promising to cut through rust or stubborn grime use special amines for their punch. 2-Ethylamine helps companies build those highly effective cleaning agents. These products need solvents and agents that work on many surfaces, from car engines to food-processing plants. Chemists lean on this tough little chemical because it works well without leaving a troublesome residue.

Working with chemicals like 2-Ethylamine brings responsibility. It evaporates quickly and can irritate skin, eyes, and lungs, so plants must have solid ventilation and good training in place. Over the years, safety rules in places like Europe and the US have gotten tighter. Most large producers invest in close monitoring of emissions and handling processes. Smaller workshops still face hurdles, trying to balance costs with safety. It’s not impossible, but it does take serious effort to train staff well and stay on top of regulations.

Anyone paying attention to supply chains knows chemicals like this face mounting scrutiny over waste and emissions. Researchers keep searching for renewable feedstocks—plant-based routes that aim to lower the environmental impact. The road is long since switching chemistry at a massive scale takes patience and investment, not just good lab results. Still, with regulations and consumer pressure growing, producers can’t afford to ignore green chemistry for much longer.

2-Ethylamine won’t appear in glossy ads or brand labels, but its footprint runs through everything from sofas to salad bowls. Getting its use right, keeping eyes open for better ways to produce and handle it, and treating the risks with respect—these steps affect more than just factories. Every time industry manages those demands, it makes life safer for workers and helps the broader community breathe easier.

2-Ethylamine packs a pretty strong punch. This colorless liquid smells a lot like ammonia, and beneath that sharp kick it brings some real hazards to the table. I’ve worked in chemical plants that had these kinds of amines sloshing around in drums. People get a little too comfortable, and that’s when things go wrong. Eyes start to sting, throats burn, skin gets red and angry. You hear about a splash, you scramble for eyewash. These accidents show that anyone handling 2-ethylamine can’t skate by without proper safety habits. There’s no casual approach that works here—this stuff will teach you quickly if you try.

Letting fumes build up is just asking for trouble. 2-Ethylamine evaporates fast and those vapors irritate eyes and lungs. In my shifts, the best labs always ran heavy-duty ventilation. You walk into a whiff of this stuff, you step back fast and make sure extractor fans are humming. Open-air mixing or pouring only makes sense under hoods or with strong local exhaust—the difference shows up in safer, clearer air and workers who aren’t constantly coughing.

People try to cut corners on gloves or glasses. I learned the hard way—wiped a bit off my glove once, forgot about it, then itched my cheek. Suddenly, a small spot felt like a swarm of bees. Real gloves (nitrile or butyl rubber) give hands a fighting chance. Safety goggles stop a splash from burning your eyes. Chemical-resistant aprons aren’t just for chemists who want to look official; they keep your skin out of harm’s way. I keep a spare pair of gloves nearby because you never know when one will tear, and it always seems to happen right as you move a container.

Drums and bottles need tight, sealed lids; even a small leak stinks up the place in minutes. Heat and sunlight both speed up evaporation, so cool, dark storage areas are your friend. I walked into one warehouse in July and nearly got bowled over by fumes from a leaking drum left in a sunbeam. Now, I remind folks—label every container, keep incompatible chemicals far apart, especially acids. Once, someone stored amines near an acid wash station. Result? Tank hissed, people scattered, and the building got shut for a full day. Get the basics right, and you avoid the big messes.

Even if you’re careful, things go sideways fast. One coworker tipped a beaker, got a splash on his arm. The safety shower was ready, and fifteen seconds under icy water made all the difference—he walked away with just redness instead of a trip to the hospital. I’ve always believed in running real practice drills. Keep spill kits where you can actually grab them. Fire extinguishers help, but foam or CO2 ones, not water—amines can react pretty wildly. If you don’t train for the mess, you’ll panic when the alarm goes off.

People follow safety rules if they feel their workplace values them. I’ve seen companies talk big about “zero incident” cultures, but real shifts happen when coworkers look out for each other. Reminders at the start of a shift, posters by storage cabinets, quick checkups between tasks—none of that feels like a nuisance when you remember how nasty a burned eye or chemical rash can get. Treating 2-ethylamine with the respect it deserves—to me, it’s not about red tape, it’s just common sense after you’ve worked with it awhile.

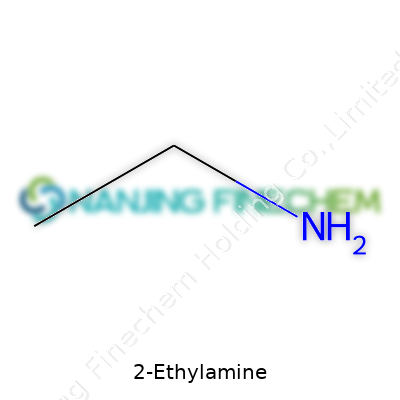

You see a new chemical name pop up and a question usually follows—“What does this stuff look like at the molecular level?” That’s the case with 2-Ethylamine. If you spend any time around a chemistry lab or in an industrial workspace, you might spot the label and wonder: what are we really dealing with?

The chemical formula for 2-Ethylamine is C2H7N. It looks simple at first glance. You have two carbons, seven hydrogens, and one nitrogen. But the real story hides in the arrangement. It connects to experiences I’ve had watching students struggle with drawing structures and naming conventions, especially with something as straightforward—yet easily mixed up—as an ethyl group.

2-Ethylamine owes its identity to that little ethyl chain bonded to an amino group. It’s not the only way to arrange those atoms, of course, but this configuration makes it stand out. You can actually “smell” molecular differences like this in labs: 2-Ethylamine gives off a strong, somewhat fishy odor, a quirk that hits you if you're anywhere near an open flask. Small details like these spark a memory—seeing someone wrinkle their nose and realize quickly just what they’ve got.

In the bigger picture, formulas like C2H7N aren’t just numbers. They save time, cut down miscommunication, and prevent dangerous mix-ups. In classrooms and jobs alike, there’s real value in a simple, direct answer—especially if a wrong guess leads to more than a red mark on an exam.

People sometimes think of chemical formulas as just homework puzzles. Precision pays off in industry, though. I remember a colleague spilling a tiny amount of a different amine—just because labels got mixed up—and the clean-up kept us late for hours. Mistakes with formulas can hurt more than your pride. Safety, handling, and waste disposal all trace back to knowing what’s in a bottle.

If you’ve ever tried to make sense of a safety data sheet, you’ll notice how chemical formulas help decide personal protective gear and emergency plans. C2H7N isn’t benign—its volatility, the way it reacts, and the fumes it gives off mean you want no guesswork.

Regulation and shipping also hinge on formulas. Governments don’t care if it “looks right,” they need to know what’s being shipped and stored. Neighbors living near chemical plants? They want facts, not assurances, about chemical identities.

Schools could do more to push for hands-on learning with real chemicals instead of dry, formula memorization. Accident prevention shouldn’t rely on lucky guesses. If every student—and every new worker—handles small samples of 2-Ethylamine with coaching, you cut back sloppy errors and boost confidence.

Digital labeling helps now too: barcodes and quick mobile scans mean you don’t have to trust faded writing on a bottle. Still, old-fashioned muscle memory—knowing C2H7N by sight—never goes out of style.

Grabbing for the formula isn’t about trivia. It’s about trust, safety, and real understanding. There’s always a story behind each collection of letters and numbers, and 2-Ethylamine’s C2H7N is no exception.

If you ask someone who’s clocked time in a lab or chemical plant about 2-ethylamine, you’ll hear stories about its sharp odor trailing down hallways and the flaming warnings stamped on its drum. This isn’t a substance you toss on a shelf. It demands more from you. Walk into any supply room where workers respect their lungs and you’ll find 2-ethylamine stored in thick-walled metal containers, far from heat or ignition sources.

So, why sweat about storing this specific amine? 2-ethylamine flashes at low temperatures, sending off vapors that catch fire quicker than most people realize. I still remember an old colleague who nearly paid a steep price for leaving a container next to a plugged-in hot plate. Safety data sheets spell it out: store in cool, dry places with plenty of ventilation. The chemical evaporates fast, so even a small spill can turn a room into a hazard zone if nobody’s paying attention.

The stuff’s not just flammable. Breathing it in burns your throat and eyes. Working nights with sloppy ventilation nearly always ends with irritated sinuses. So, facility managers wind up spending good money on air systems that keep vapors from lingering. Some people cut corners to save cash, but those savings never last. A single accident wipes them out and then some.

I’ve seen teams break down big drums into smaller, clearly labeled bottles to cut down on accidental exposure. Workers double check caps and seals before walking away. Storing 2-ethylamine near acids or oxidizers? That’s a rookie mistake that can cause violent reactions. Facilities putting it away keep incompatible chemicals separated by solid barriers or even by storing them in different rooms altogether. It isn’t paranoia when a single oversight can send someone to the ER.

Nobody wants to worry about their warehouse getting too warm, but with 2-ethylamine, heat is an enemy. Good storage means picking spots out of the sun, away from hot equipment or open flames. Some shops even monitor temperatures year round, just to be sure things don’t creep up into the danger zone. From my own experience, the hassle of extra AC or fans beats the chaos of an emergency shut down.

Fire extinguishers must flank every area where 2-ethylamine is stored. Not every extinguisher works; dry chemical models smother solvent fires properly, so workers keep them within arm’s reach. Eye washes and safety showers sit right outside the storage room door—nobody wants to hunt for relief if someone takes a splash to the face. Regular emergency drills help teams act fast when seconds count.

There’s no trick to storing 2-ethylamine safely—just lots of care, clear labeling, and training that sticks. Some companies invest in digital inventory systems for tracking both containers and conditions. Others stick with old-school checklists, but double up on spot inspections and paperwork audits. What really makes the difference: a crew that respects what’s at stake and backs each other up. That’s how you turn storage into a routine, not a gamble.

People come across the word "2-Ethylamine" and wonder if they’re safe around it. This compound finds its way into places like chemical manufacturing, pharmaceuticals, and sometimes research labs. On paperwork and safety sheets, you’ll see caution signs. This is not just bureaucracy talking. 2-Ethylamine isn’t something you want splashing on your skin or swirling through the air where you breathe all day.

Breathing fumes from this chemical or getting it on your skin brings immediate discomfort. Think stinging eyes, irritated skin, and even a rush of headache or nausea if you get too close. There are stories of workers describing a sharp smell—sort of like ammonia but with an extra poke. These are not tricky symptoms; they’re your body’s way of raising a red flag.

A sudden splash? You might feel your skin burn and eyes water. Regular exposure, though, seems to bring other hazards. Folks who have worked around chemicals like this one sometimes deal with chest tightness, or even struggle with breathing over time. Animal studies pile on more concern. Reports link repeated or heavy exposures to liver or kidney stress, and not just in some faraway lab—regulations and evidence come straight from health agencies like the CDC and European Chemicals Agency.

Looking for the real threat, it’s the way this chemical reacts with your body on contact or when inhaled. There’s no large-scale human study that lists out all the possible diseases, but enough smaller reports exist to keep the warning lights flashing. No need for a person to panic, but nobody wins prizes for brushing off these risks.

This isn’t something most folks run into on the street or at home. Real risk falls mostly on workers—those who spend whole shifts handling or storing chemicals. For the average person, the chance of trouble sits close to zero. The story changes inside a chemical plant, a lab, or anywhere that processes raw chemicals. Here, even a broken seal on a storage drum turns into a real problem.

There’s no magic fix, but there’s plenty to do that makes working around 2-Ethylamine safer. Gloves, goggles, respirators—these aren’t overkill. Anyone who’s had a minor splash without gear quickly learns to never skip protection again. Well-run plants usually put air monitors in high-risk areas to keep levels down. Simple steps, like good ventilation and safe storage, lower most risks to the point where folks can do their jobs safely.

I remember touring a plant during a safety audit. The crew wore full-on gear and rinsed any surface that got hit with chemicals, treating “near-misses” as seriously as accidents. They even ran weekly drills just for chemical spills. That sort of culture doesn't spring up by accident. It takes leadership and commitment to prevent shortcuts. Watching how they respected every warning label made it clear—protection isn’t about red tape, it’s about coming home healthy.

Real safety comes down to respect—respect for the hazards and for people. Cutting corners, skipping gear, underestimating fumes—these are the patterns that lead to problems. Anyone who works around chemicals like 2-Ethylamine owes it to themselves and their crew to treat every whiff, splash, and leak as a serious matter. Health doesn’t come back as easily as spilled product does.

With good habits, reliable safety measures, and the right attention, people can handle even tough chemicals without joining the next set of incident reports. It’s all about the right mix of knowledge, experience, and daily care.

| Names | |

| Preferred IUPAC name | ethan-1-amine |

| Other names |

Ethyl-2-amine Ethylamine Monoethylamine MEA |

| Pronunciation | /tuː ˈɛθɪl.eɪ.miːn/ |

| Identifiers | |

| CAS Number | 109-89-7 |

| 3D model (JSmol) | `/socket/JSmol.jsp?model=C(CN)C&is3d=true` |

| Beilstein Reference | 632379 |

| ChEBI | CHEBI:16049 |

| ChEMBL | CHEMBL1232367 |

| ChemSpider | 54152 |

| DrugBank | DB14141 |

| ECHA InfoCard | 03b1eaf7-c7aa-4b1d-86be-5fe20c7a2cea |

| EC Number | 202-468-7 |

| Gmelin Reference | 5839 |

| KEGG | C01856 |

| MeSH | D000463 |

| PubChem CID | 12001 |

| RTECS number | KH2975000 |

| UNII | 59AE81261Y |

| UN number | UN2270 |

| Properties | |

| Chemical formula | C2H7N |

| Molar mass | 46.085 g/mol |

| Appearance | Colorless liquid |

| Odor | Ammonia-like |

| Density | 0.682 g/mL at 25 °C |

| Solubility in water | Miscible |

| log P | -0.26 |

| Vapor pressure | 5.61E+03 mmHg at 25 °C |

| Acidity (pKa) | 10.8 |

| Basicity (pKb) | 3.27 |

| Magnetic susceptibility (χ) | -5.1 × 10⁻⁹ cm³/mol |

| Refractive index (nD) | 1.378 |

| Viscosity | 0.3 mPa·s (at 20 °C) |

| Dipole moment | 1.33 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 189.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -49.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | –3734 kJ/mol |

| Pharmacology | |

| ATC code | C01CA23 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Danger |

| Hazard statements | H225, H302, H314 |

| Precautionary statements | P210, P260, P280, P304+P340, P305+P351+P338, P312 |

| NFPA 704 (fire diamond) | 2-3-0 |

| Flash point | -17 °C |

| Autoignition temperature | 367 °C |

| Explosive limits | 3% - 13.4% |

| Lethal dose or concentration | LD50 oral rat 472 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral-rat LD50: 472 mg/kg |

| NIOSH | KH8575000 |

| PEL (Permissible) | PEL: 5 ppm |

| REL (Recommended) | 30 mg/m3 |

| IDLH (Immediate danger) | 30 ppm |

| Related compounds | |

| Related compounds |

Ethylamine Dimethylethylamine Diethylamine Triethylamine |